Basic Info.

Model NO.

Y-3*160

Customized

Customized

Advantage

Use Widely

Condition

New

Transport Package

Standrad

Trademark

YSDCNC

Origin

Nanjing

HS Code

8462319000

Production Capacity

600sets

Product Description

hydraulic angle corner shearing machine for sale

notching machine

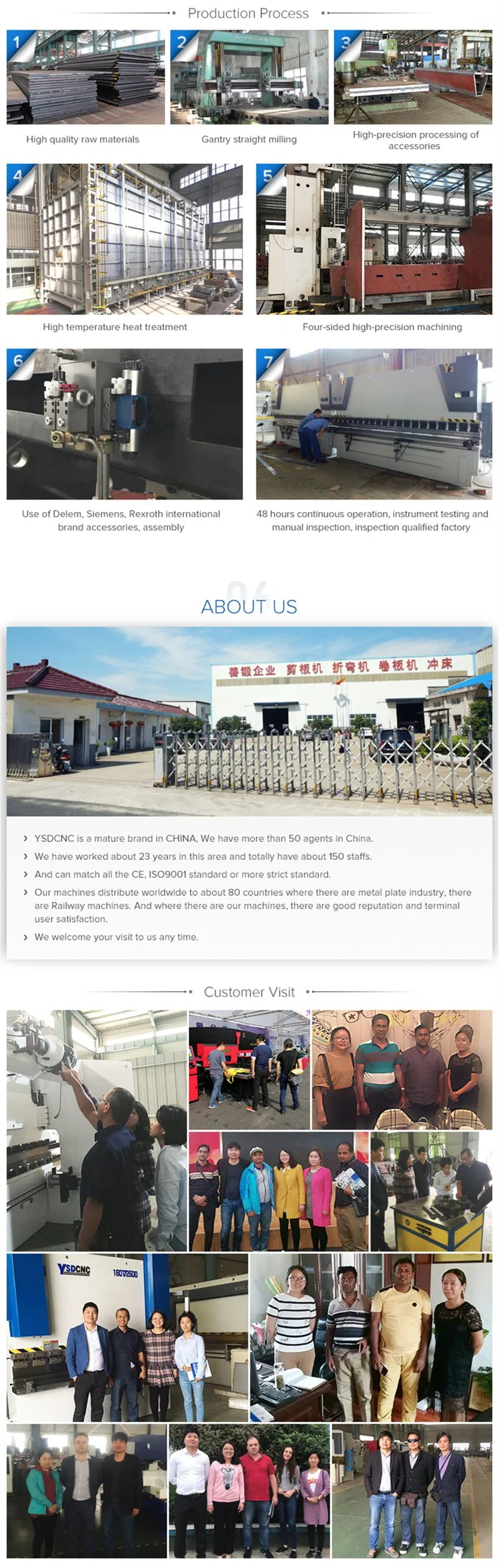

YSD duct production machines are: automatic duct production line, CNC Angle steel flange production line, double (single)linkage TDF flange machine, Angle code mould, plasma cutting machine, seven functions locking machine, manual( pneumatic )crimping machine, five lines (seven lines) beading machine, Angle crimping machine, reel shear beading machine ,leveling bending machine,steel-bend type,horizontal shrimp bend machine,pneumatic joint machine,Angle setter,bias samsung rolling machine.

This angle hydraulic corner cutting machine , adjustable 4mm angle notching machine is kind of special cutting equipment, used in sheet metal processing edge or corner of the triangle gap, which is widely used in electrical appliances, metal cabinet body, ventilation equipment, kitchen equipment, decorative materials, such as sheet metal processing field. The hydraulic system on our machine is reliable, professional manufacturer of custom tanks, the use of domestic brand name long source pumps, and Rexroth valve. Professional tools, long life, suitable for cutting carbon steel and stainless steel plate.

1 Hydraulic notching machine also can be called corner notching machine or angle notching. For usual hydraulic corner notching machine can divided in two kind, that is variable notching machine and fixed angle Notching machine.

The angle cutting of fixed type is 90°, of course you can cutting the metal to 40 °to 135°if you are smart enough. As the adjustable angle (variable notching machine) the metal cutting range from 40 ° to 135 °.

2 The efficiency can be developed about 1/2 compared with the nonadjustable type. Moreover, it can adjust its working angle from its ability such as 4*200 variable type, it can adjust its angle from 40 °to 135°,

you can do any angle within this angle range. In other words, any metal cutting performance can achieve the desired state.

3 The main structure of the machine is composed of whole welded steel plate, which means durable and robust. The machine only need to be equipped with the baldies to meet the needs of the general sheet metal processing job.

Not like ordinary punch machine, usually need to change and make a new sets of molds just for some certain angle.

4 Take our corner notching into use, reducing the cost and reduce the tediously long time for frequently mold-clamping, improve work efficiency, reduce labor intensity, avoid workers' high risk of usual power press working,

while lower noise caused and create a quiet working environment.

5 Notching machine for cutting sheet metal, which is widely used in many fields of automobile manufacturing, boating, elevators, electrical equipment, plumbing, cooking utensils and stainless steel products.

notching machine

notching machine

YSD duct production machines are: automatic duct production line, CNC Angle steel flange production line, double (single)linkage TDF flange machine, Angle code mould, plasma cutting machine, seven functions locking machine, manual( pneumatic )crimping machine, five lines (seven lines) beading machine, Angle crimping machine, reel shear beading machine ,leveling bending machine,steel-bend type,horizontal shrimp bend machine,pneumatic joint machine,Angle setter,bias samsung rolling machine.

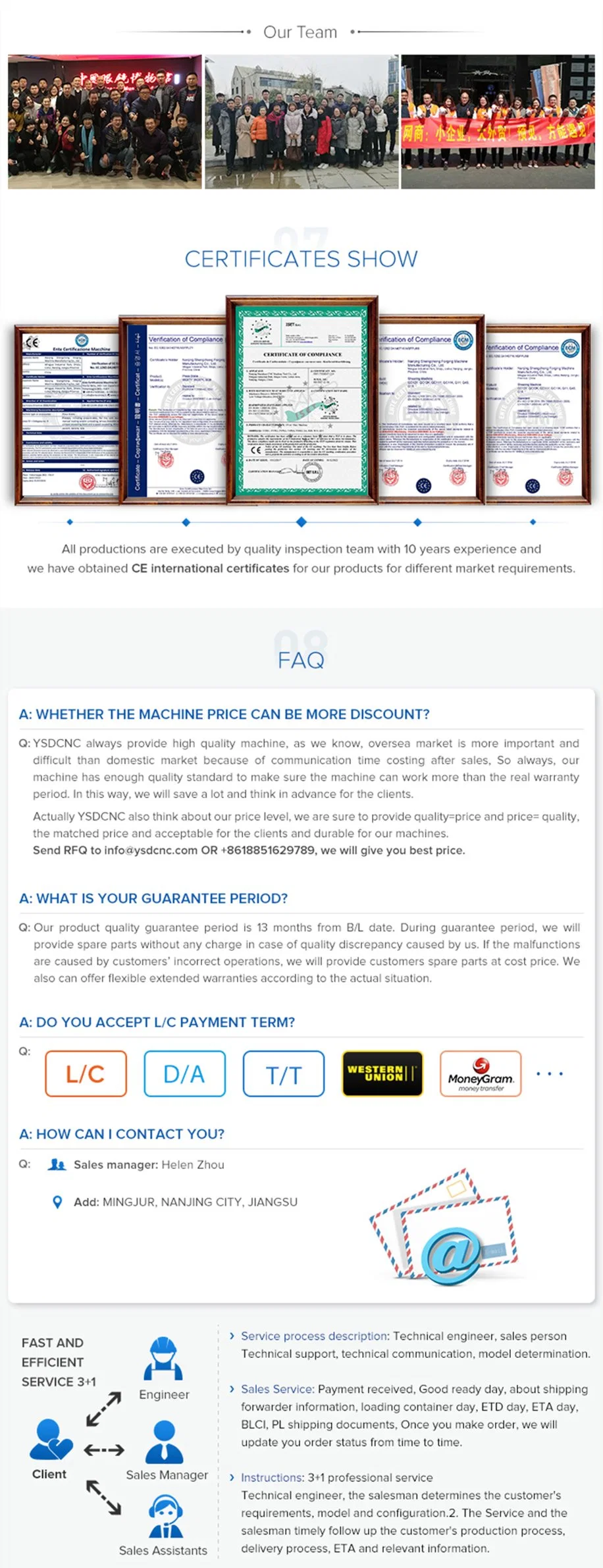

| Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

| Brand: YSDCNC |

| Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

| Tel:+86 025-57262305 Phone:+86 18851629789 |

| Website: www.ysdcnc.com |

This angle hydraulic corner cutting machine , adjustable 4mm angle notching machine is kind of special cutting equipment, used in sheet metal processing edge or corner of the triangle gap, which is widely used in electrical appliances, metal cabinet body, ventilation equipment, kitchen equipment, decorative materials, such as sheet metal processing field. The hydraulic system on our machine is reliable, professional manufacturer of custom tanks, the use of domestic brand name long source pumps, and Rexroth valve. Professional tools, long life, suitable for cutting carbon steel and stainless steel plate.

1 Hydraulic notching machine also can be called corner notching machine or angle notching. For usual hydraulic corner notching machine can divided in two kind, that is variable notching machine and fixed angle Notching machine.

The angle cutting of fixed type is 90°, of course you can cutting the metal to 40 °to 135°if you are smart enough. As the adjustable angle (variable notching machine) the metal cutting range from 40 ° to 135 °.

2 The efficiency can be developed about 1/2 compared with the nonadjustable type. Moreover, it can adjust its working angle from its ability such as 4*200 variable type, it can adjust its angle from 40 °to 135°,

you can do any angle within this angle range. In other words, any metal cutting performance can achieve the desired state.

3 The main structure of the machine is composed of whole welded steel plate, which means durable and robust. The machine only need to be equipped with the baldies to meet the needs of the general sheet metal processing job.

Not like ordinary punch machine, usually need to change and make a new sets of molds just for some certain angle.

4 Take our corner notching into use, reducing the cost and reduce the tediously long time for frequently mold-clamping, improve work efficiency, reduce labor intensity, avoid workers' high risk of usual power press working,

while lower noise caused and create a quiet working environment.

5 Notching machine for cutting sheet metal, which is widely used in many fields of automobile manufacturing, boating, elevators, electrical equipment, plumbing, cooking utensils and stainless steel products.

| Adjustable Angle hydraulic Angle shears | |||||||

| Tpye Item | Unit | 4*200 | 6*220 | ||||

| Shearing thickness | common steel | mm | 0.5-4.0 | 0.5-6.0 | |||

| stainless steel | mm | 0.5-2.0 | 0.5-3.0 | ||||

| Shearing length | mm | 200 | 220 | ||||

| Shearing Angle | ° | 40°-135° | 45°-135° | ||||

| Slide strokes Per Minute | n/min | ≥35 | ≥30 | ||||

| Worktable height | mm | 850 | 850 | ||||

| Motor Power | kw | 3 | 4 | ||||

| Dimension | L | mm | 890 | 950 | |||

| W | mm | 870 | 920 | ||||

| H | mm | 1080 | 1150 | ||||

| Weight | KG | 860 | 970 | ||||

| Fixed Angle hydraulic Angle shears | |||||||

| Tpye Item | Unit | 3*200 | 4*250 | 6*250 | 8*300 | 10*300 | |

| Shearing thickness | common steel | mm | 0.5-3.0 | 0.5-4.0 | 0.5-6.0 | 1.0-8.0 | 1.0-10 |

| stainless steel | mm | 0.5-1.5 | 0.5-2.0 | 0.5-3.0 | 1.0-4.0 | 1.0-5.0 | |

| Shearing length | mm | 200 | 250 | 250 | 300 | 300 | |

| Shearing Angle | ° | 90° | 90° | 90° | 90° | 90° | |

| Slide strokes Per Minute | n/min | ≥40 | ≥35 | ≥35 | ≥30 | ≥25 | |

| Worktable height | mm | 820 | 850 | 850 | 900 | 900 | |

| Motor Power | kw | 3 | 4 | 4 | 5.5 | 5.5 | |

| Dimension | L | mm | 810 | 910 | 910 | 950 | 1020 |

| W | mm | 720 | 760 | 810 | 820 | 910 | |

| H | mm | 980 | 1050 | 1050 | 1150 | 1190 | |

| Weight | KG | 590 | 680 | 710 | 850 | 1120 | |

notching machine