Basic Info.

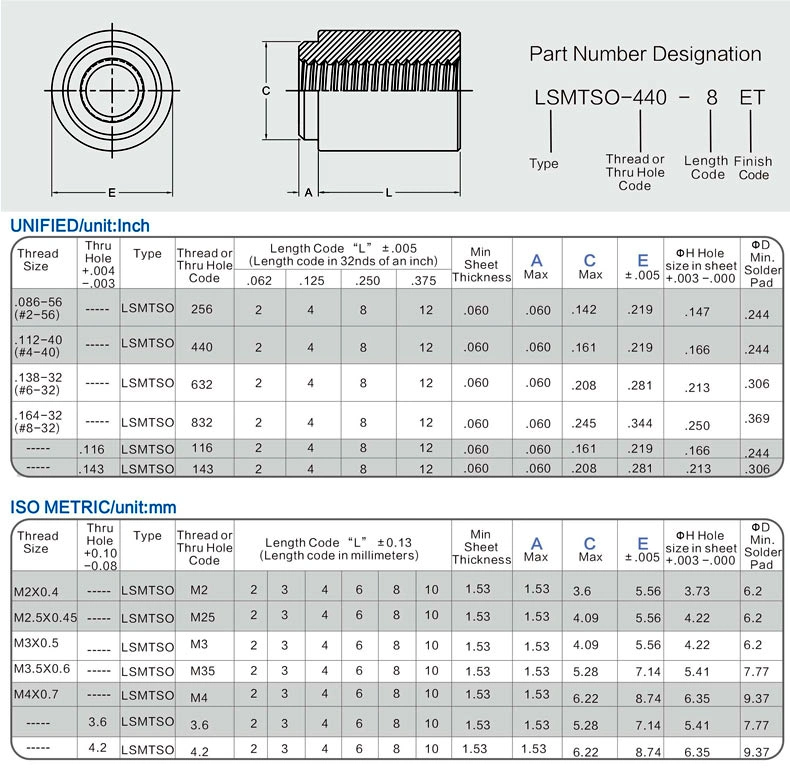

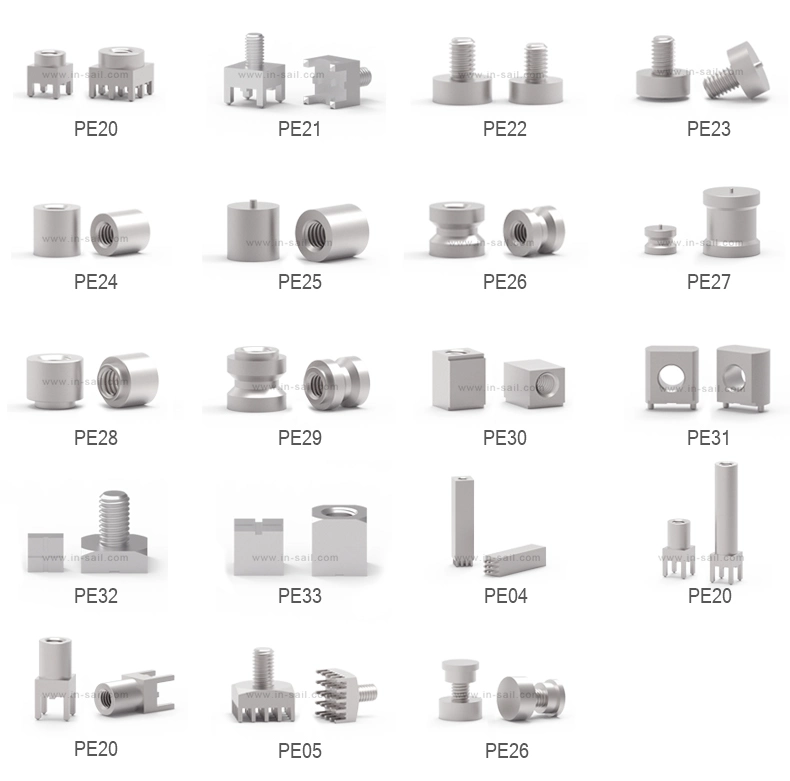

Model NO.

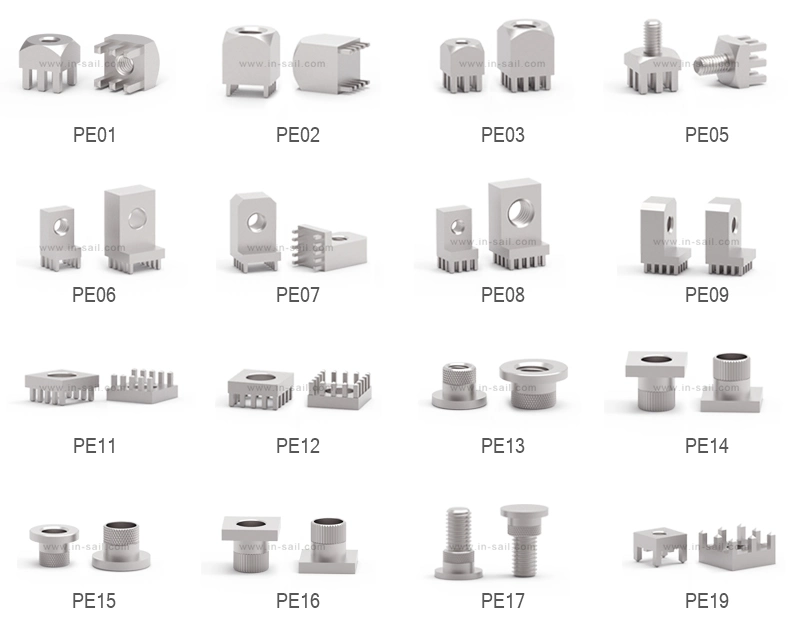

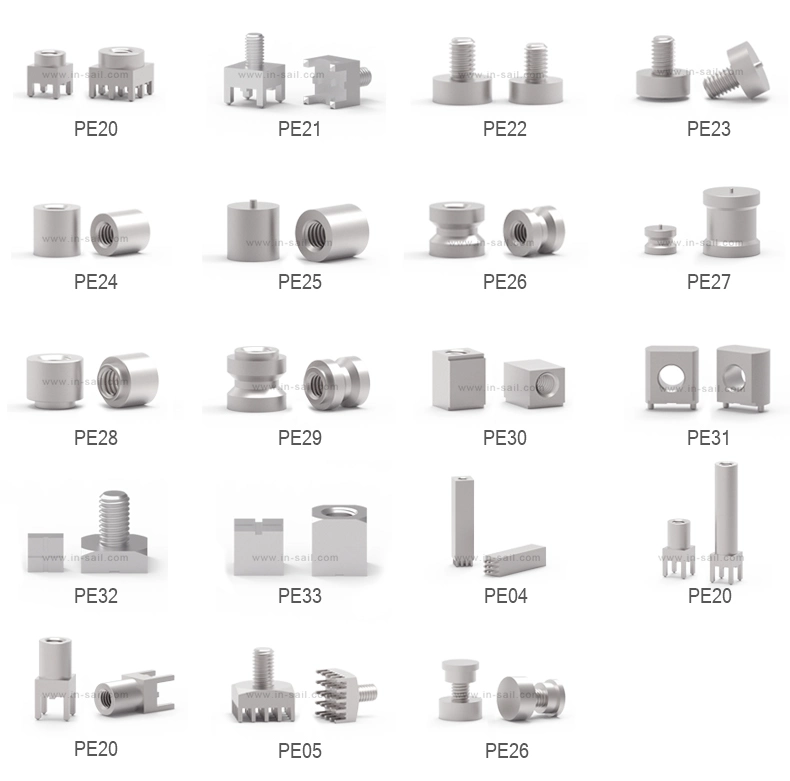

POWER ELEMENT

Shape

Other

Interface Type

Pin

Certification

RoHS, SGS

Brand

in-Sail

Surface Treatment

Tin Plated

Customization

Available

Execution

Press-Fit

Series

SMT Standoff/SMT Nut/PCB Connector

Transport Package

Blister Box Packaging+Carton

Trademark

In-saiL

Origin

Shenzhen China

Production Capacity

100000000

Product Description

Factory Direct Sales

More than 10,000 specifications of fasteners available. Fast delivery, One-stop solutions. Annual Customer praise rate exceeds 98%.

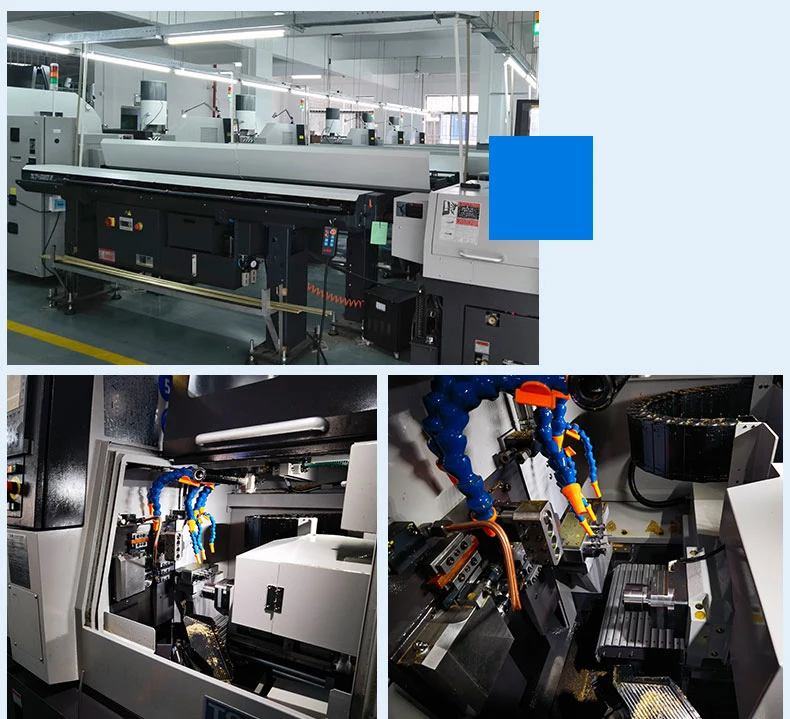

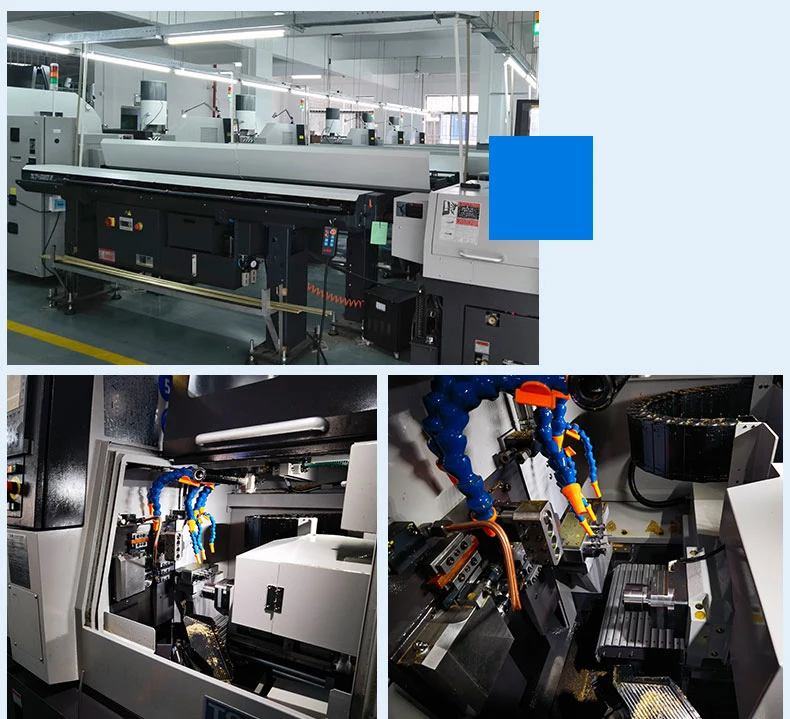

Efficient Productivity

Technical support within a half-hour, Standard product lead-time around 1-2 weeks.And provide online service 24 hours a day.

Reliability

We always insist on integrity and responsibility, constantly innovative quality products, make our product more competitive.

| Material | Aluminum alloy,Brass,Stainless Steel,Carbon steel,according to customer's requirement |

| Finish | Milled /Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized,black anodized,painting, powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Production Capability | Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' | |

| Stamping:200T max | |

| Lead Time | 5-15 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

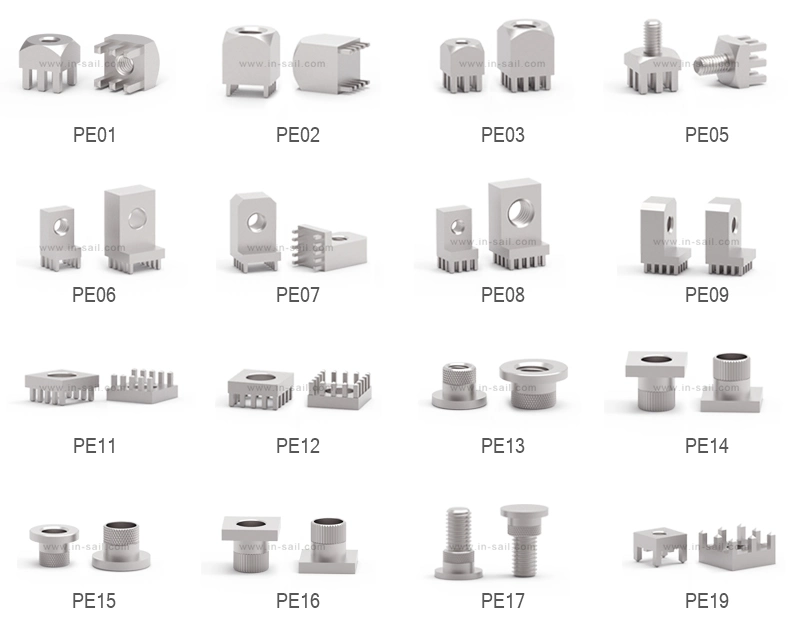

Single-piece Power Elements are used for the supply and distribution of high

currents in connection with circuit board based systems. Depending on the pin

arrangement and the layout, currents of up to 1,000A are possible. Meanwhile

this product group has been successfully used in the field in thousands of

various designs. The manufacturing method allows individual adaptions

regarding design and dimensions. That is the reason why Power Elements

perfectly qualify as connecting element for fuses, IGBTs, switches and cables

to the circuit board or as contact element for board-to-board respectively boardto-

case.

Application Possibilities

• Board-to-board over 90°o r packaging

• Wire-to-board screw connection of ring terminals

• Electro mechanics such as hinges and case mounting

• Spacers

• Retainers / fastenings of switches, fuses, IGBTs

• Any combination of all these and much more

Processing

In-saiL PowerOne Power Elements are pressed in into the circuit board.

Soldering is not necessary. Therefore, the PCBs are not exposed to

temperature stress. This processing step easily blends in to the processing

chain and is highly cost efficient. With the aid of the corresponding Press Fit

tools, several Power Elements can be pressed in simultaneously.

• For assembling prototypes, no special equipment is needed for pressing in,

a simple toggle press is sufficient.

• The circuit board needs support during the pressing procedure.

• The pressing force must be executed in a 90° angle to the circuit board.

• After the pressing process the pins should stand out of the drilled hole (ca. 0.2

- 0.5 mm).

• Plated through holes of the circuit board must be executed according to our

indications.

• PowerOne high current terminal blocks and spacers are manufactured for

pressing, soldering is not intended.

currents in connection with circuit board based systems. Depending on the pin

arrangement and the layout, currents of up to 1,000A are possible. Meanwhile

this product group has been successfully used in the field in thousands of

various designs. The manufacturing method allows individual adaptions

regarding design and dimensions. That is the reason why Power Elements

perfectly qualify as connecting element for fuses, IGBTs, switches and cables

to the circuit board or as contact element for board-to-board respectively boardto-

case.

Application Possibilities

• Board-to-board over 90°o r packaging

• Wire-to-board screw connection of ring terminals

• Electro mechanics such as hinges and case mounting

• Spacers

• Retainers / fastenings of switches, fuses, IGBTs

• Any combination of all these and much more

Processing

In-saiL PowerOne Power Elements are pressed in into the circuit board.

Soldering is not necessary. Therefore, the PCBs are not exposed to

temperature stress. This processing step easily blends in to the processing

chain and is highly cost efficient. With the aid of the corresponding Press Fit

tools, several Power Elements can be pressed in simultaneously.

• For assembling prototypes, no special equipment is needed for pressing in,

a simple toggle press is sufficient.

• The circuit board needs support during the pressing procedure.

• The pressing force must be executed in a 90° angle to the circuit board.

• After the pressing process the pins should stand out of the drilled hole (ca. 0.2

- 0.5 mm).

• Plated through holes of the circuit board must be executed according to our

indications.

• PowerOne high current terminal blocks and spacers are manufactured for

pressing, soldering is not intended.