- Overview

- Product Description

- Detailed Photos

- Related Products

- LITONE Service

- Company Profile

- Application

- FAQ

Basic Info.

Packaging & Delivery

Product Description

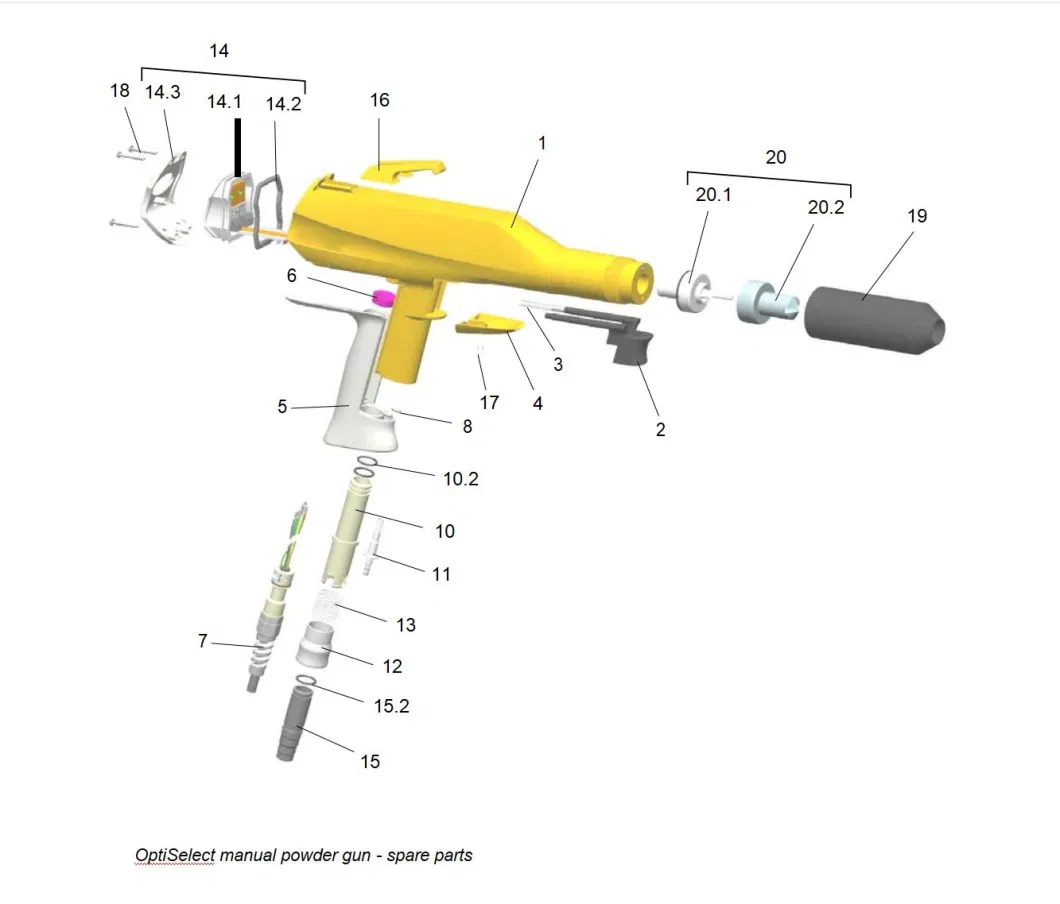

GM Auto Powder Coating System Manual Powder Coating Machine Spray Gun Optiselect Gun GM02 Gun Threaded Sleeve Complete 1000 948

1. BRIEF INTRODUCTION

OptiSelect GM02 uses special anti-static materials to make gun shell and gun nut, in order to protect the high voltage from running away, output voltage of cascade is 85~95 kV and output stability.

The cascade casing is made of G gun casing material, which is of high quality.

The production process is different, and it is directly potted in a vacuum environment, so there will be no air bubbles.

2. TECHNICAL PARAMETER

| Electrical data | |

| Nominal input voltage | 10 V eff. |

| Nominal output voltage | 98 kV |

| Polarity | negative (option: positive) |

| Max. output current | 100 μA |

| Cascade | 12 stages |

| Ignition protection | Type A acc. EN 50177 |

| ||

A | OptiSelect manual powder gun - complete negative polarity, incl. gun cable - 6 m, rinsing air hose - 6 m, flat jet nozzle, brush and parts kit, without powder hose | 1002 100 |

| OptiSelect manual powder gun - complete positive polarity, incl. gun cable - 6 m, rinsing air hose - 6 m, flat jet nozzle, brush and parts kit, without powder hose | 1002 101 | |

| B | OptiSelect manual powder gun shaft (incl. cascade) | |

| Negative polarity (-) | 1001 891 | |

| Positive polarity (+) | 1001 892 | |

| C | Cascade (negative polarity) - complete | 1000 809 |

| Cascade (positive polarity) - complete | 1002 031 | |

| 1 | Gun body | 1001 155 |

| Handle - complete set (pos. 5, 6, 7 and 8) | 1000 807 | |

| 2 | Trigger - complete (incl. pos. 2 and 3) | 1001 341 |

| 3 | Compression spring - 0.36x4.2x49.4 mm | 1001 487 |

| 4 | Trigger cover | 1000 801 |

| 5 | Grasp termination | 1000 806 |

| 6 | Radial gasket | 1000 803 |

| 7 | Gun cable - L=6 m, complete | 1001 528 |

| Extension cable for gun cable - L=6m, incl. safety clamp | 1002 161 | |

| Extension cable for gun cable - L=14m, incl. safety clamp | 1002 162 | |

| Safety clamp for extension cable | 1002 064 | |

| 8 | Grub screw - M3x8 mm | 1000 844 |

| 10 | Powder tube - complete | 1001 339 |

| 10.2 | O-ring - Ø 12x1.5 mm | 1000 822 |

| 11 | Rinsing air connection | 1000 804 |

| 12 | Clip ring | 1000 898 |

| 13 | Compression spring | 1001 488 |

| 14 | Back cover - complete | 1000 617 |

| 14.1 | Printed circuit board holder - complete (incl. pos. 14.2) | 1002 029 |

| 14.2 | Radial gasket | 1000 795 |

| 14.3 | Shield - complete | 1002 028 |

| 14.4 | Cap screw - M3x8 mm (not shown) | 202 363 |

| 15 | Hose connection - complete, for internal hose Ø 11-12 mm | 1001 340 |

| Hose connection - complete, for internal hose Ø 9-10 mm | 1002 030 | |

| 15.2 | O-ring - Ø 12x1.5 mm | 1000 822 |

| 16 | Hook (replaceable) | 1000 877 |

| 17 | Countersunk head screw - M4x8 mm, plastic | 263 516 |

| 18 | PT-screw | 1000 843 |

| 19 | Threaded sleeve - complete | 1000 948 |

| 20 | Flat jet nozzle - complete | 1000 047 |

| 20.1 | Electrode holder - complete | 1000 055 |

| 20.2 | Flat jet nozzle | 1000 049 |

| OptiSelect adaptor for PGC control unit (not shown) | 1001 952 | |

| Cleaning brush - Ø 12mm | 389 765 | |

| Parts set (not shown), consisting of: | 1002 359 | |

| Round jet nozzle - NS02, complete | 382 922 | |

| Cable clamp | 303 070 | |

| Deflector plate - Ø 16 mm | 331 341 | |

| Deflector plate - Ø 24 mm | 331 333 | |

| Deflector plate - Ø 32 mm | 331 325 | |

| Hose connection - complete, for internal hose Ø 11-12 mm | 1001 340 | |

| O-ring - Ø 12x1.5 mm | 1000 822 | |

| Countersunk head screw - M4x8 mm, plastic | 263 516 | |

| Powder hose - Ø 10 mm (not shown) | 1001 673 | |

| Powder hose - Ø 11 mm (not shown) | 105 139 | |

| Packing | High quality carton and wooden box |

| Delivery Time | Four to eight days after payment by air |

We not only supply the high-quality coating equipment,but also the best service.

After market service

Warranty service

OEM service

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

Ours Coating has a specialized and efficiency working team. If you are new on the coating, that some pictures or drawings of your products and workshop shown to us will be appreciated, we will give you specialized suggestion of whole work.

2. Shipping Service

Ours Coating has a specialized and independent department for shipping the buyer's goods. The workers know T/T, L/C terms well. All Exported documents could be made perfectly. We cooperate with the most famous shipping company in China also. They could provide the best and economic shipping ways to the buyer's port.

3. Installation Service

Installation Service is available with all our machines. Ours Coating will dispatch technicians to the Buyer's factory to install and trial operate the equipment.

4. Clients' Training Service

Ours Coating can accept that the buyer arranges their own technicians to our factory to learn how to operate machines. Also, training in the installation period is better acceptable.

5. After Sales Service

Ours Coating will provide one year warranty period. Many spare parts will be prepared in the tool box together with machines.

Litone Machinery Co., Ltd. is a leading supplier in the field of electrostatic powder coatings worldwide.

From simple manual coating to fully automatic powder coating, our company provides solutions that can meet the high requirements of customers from all over the world in a wide range of industrial fields.

These technologically advanced, high-quality equipment and systems are developed and manufactured at Litone's headquarters in Weifang, China.

Customers can use the most advanced coating laboratory for coating experiments.

These findings are then integrated into the design of complex coating systems to tailor solutions for customers. Affiliated companies in Germany, the United Kingdom, the United States, Italy, France, India, Spain and Mexico and an extensive international distributor network in more than 60 countries/regions sell products to a wide range of industrial users.

Powder Coating Machine for Car wheel.

Powder Coating Machine for Bicycle frame.

Powder Coating Machine for Electrical Household Appliances.

Powder Coating Machine for Aerospace Area.

Powder Coating Machine for Fitness Equipment.

Powder Coating Machine for Track Traffic.

Powder Coating Machine for Medical Devices.

Powder Coating Machine for Petroleum Pipes, Valve.

1. Who are we?

We are based in Shandong, China, start from 2020,sell to North America(25.00%),Southeast Asia(10.00%),South Asia(10.00%),Eastern Asia(10.00%),Mid East(6.00%),Africa(5.00%),Domestic Market(5.00%),Northern Europe(5.00%),Western Europe(5.00%),Southern Europe(5.00%),South America(5.00%),Central America(4.00%),Eastern Europe(3.00%),Oceania(2.00%). There are total about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

Powder coating machine,powde coating line,powder coating gun,powder coating equipment,powder coating equipment parts

4. Why should you buy from us not from other suppliers?

Our company has more than 10 years of experience in electrostatic spraying industry, and can provide customers with various complex spraying solutions and best services, including: spraying machine, spray gun, spray room, etc

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,DDP,DDU;

Accepted Payment Currency:USD,EUR,CNY,CHF;

Accepted Payment Type: T/T,MoneyGram,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,German,Russian