- Overview

- About us

- Examples projects

- Our Focus

- Hard-working team

- Surface Finish

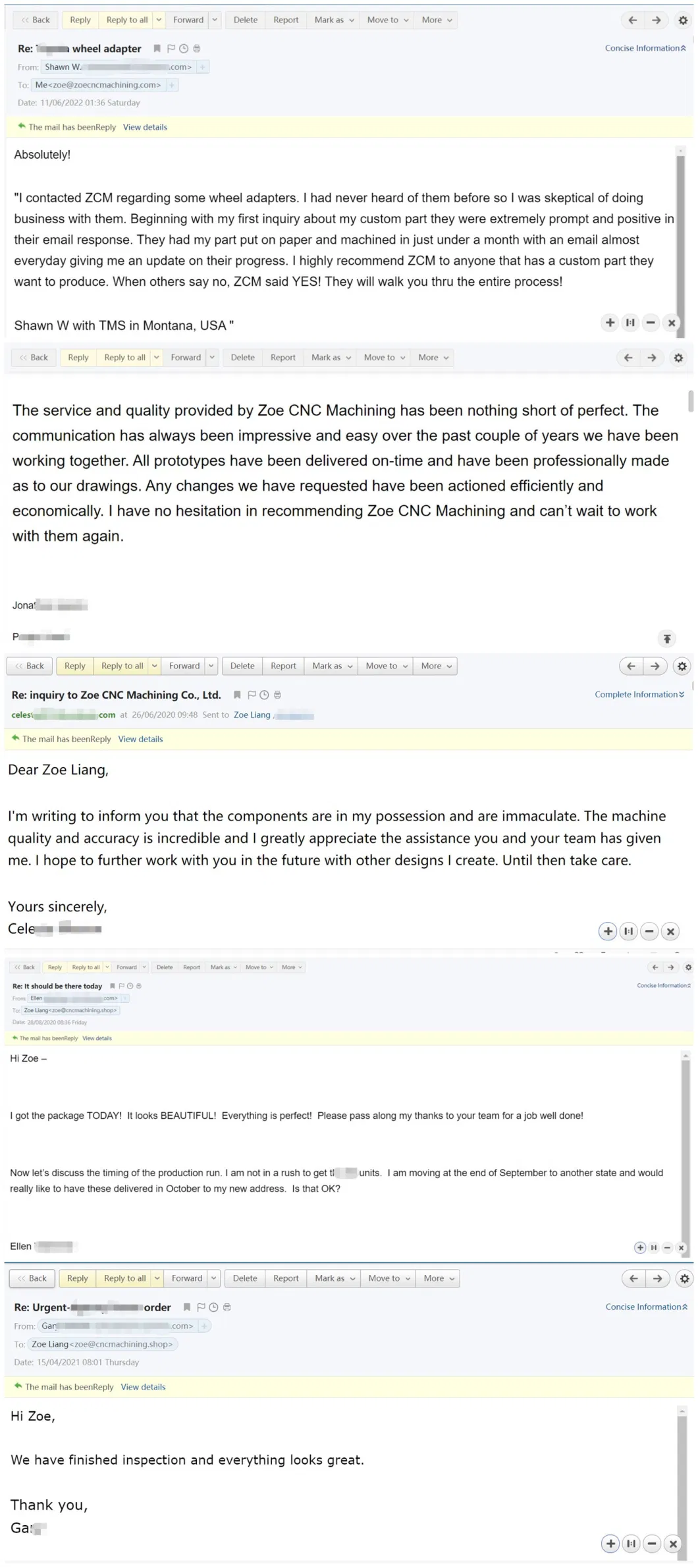

- Comments from customers

Basic Info.

Product Description

Custom made machine agricultural machinery parts Metal CNC turning machining parts Brass fitting compression

Click here and specify your inquiry, contact us to get an online quote now!

Full-service precision CNC machining services for prototypes and short and low to high production runs. Capabilities are CNC milled and turned metal parts and assemblies. Materials worked with include aluminum, brass, copper, stainless, steel, iron, other precious metals, and other plastic materials. Lead times are 2 to 3 weeks for prototypes and 4 to 6 weeks for production runs. Emergency and rush services are available. Industries served include aircraft and aerospace, consumer electronics, automotive, machinery fittings, audio equipment, EDC tools, computer, and Secondary processes such as anodizing, sandblasting, blackening, grinding, honing, heat treating, powder coating, passivation, polishing, plating, and brushing are also provided.

|  |  |  |

| Responsive We have invested significant time and effort in developing lasting relationships with both our customers, material/surface finish suppliers, and ZCM. Our ability to establish these partnerships enables ZCM to be extremely responsive. | Quality Since the beginning, we pride ourselves on supplying high-end quality, competitively priced parts to some of the Chinese most prestigious companies. By using the latest inspection technology such as 2D CMM & 3DCMM and highly qualified staff we provide accurate parts at the tightest dimensions. | Machining Services We excel in all areas of CNC milling and turning machining and Swiss machining. ZCM had machined thousands of parts for many different industries including aerospace, auto, consumer electronics, bike, and fittings, as well prototyping development products. | Assembly Services One of our strengths lies in the ability to help the assembly for our customers their full turnkey products, from simple assembly to complicated assembly, which reduces much inconvenience for any extra work on the customers' end. |