Basic Info.

Model NO.

9130

Certification

NSF, Cupc

Color

Copper

Size

1/2"-2"

Material Standard

ASTM B88

Quality Control

100% Inspection

Profile

V Profile Copper Press Fitting

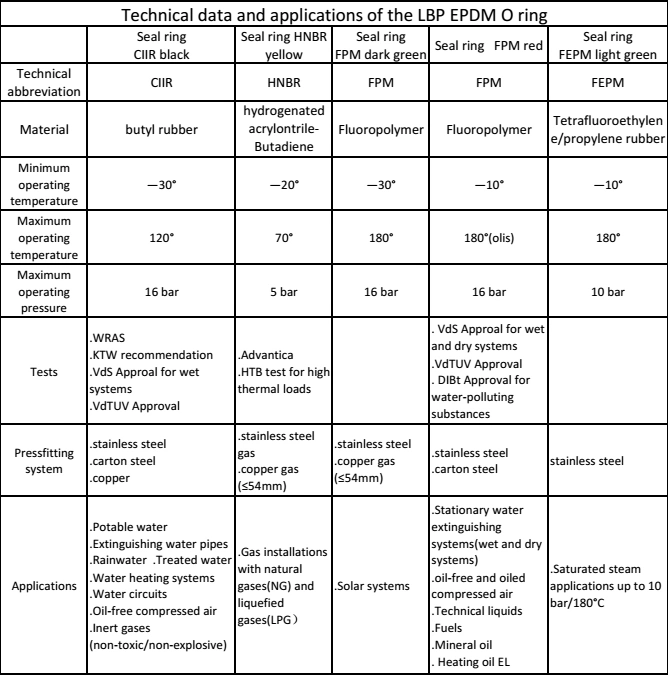

Sealing Ring Material

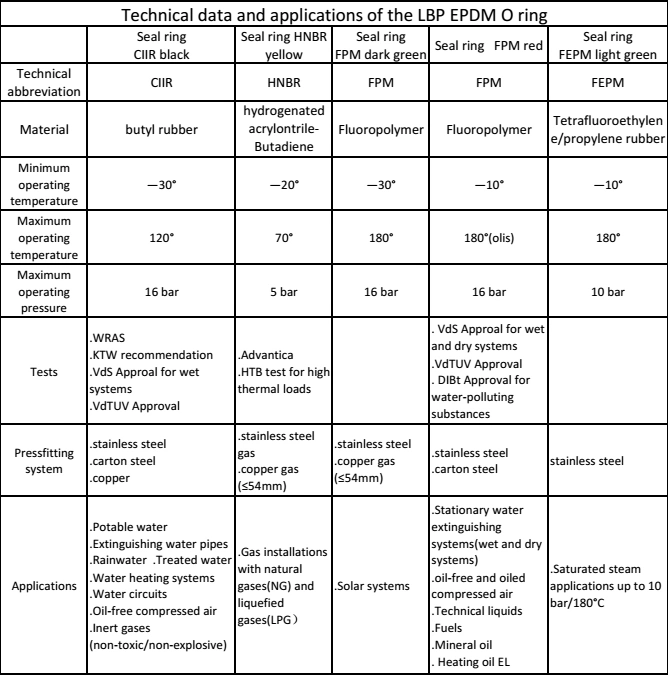

EPDM, HNBR, FKM

Operating Pressure

200psi Cwp Max

Operating Temperature Range

20°f-250°f

Approved Application

Drinking Water, Heating, Cooling, Compressed Air

Transport Package

Polybags/Ctns/Pallets

Specification

1/2" -2"

Trademark

DBW

Origin

Taizhou. China

HS Code

74121000

Production Capacity

12, 000, 000PCS/Year

Product Description

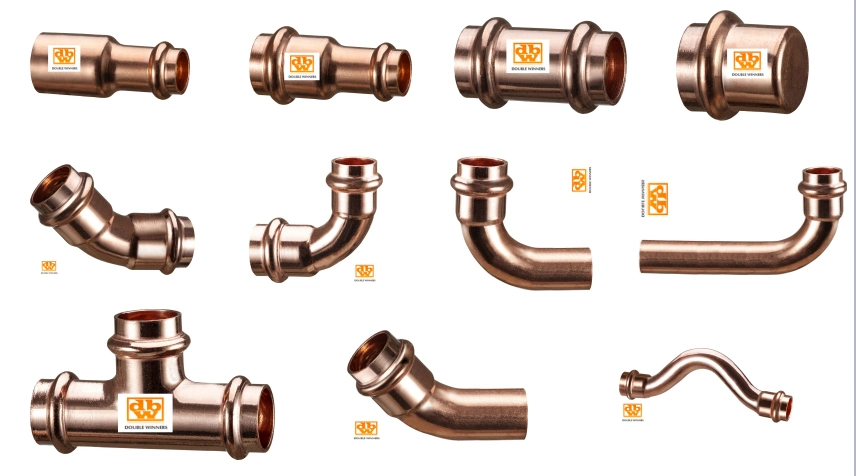

copper tee for chilled water

DBW copper press reducer

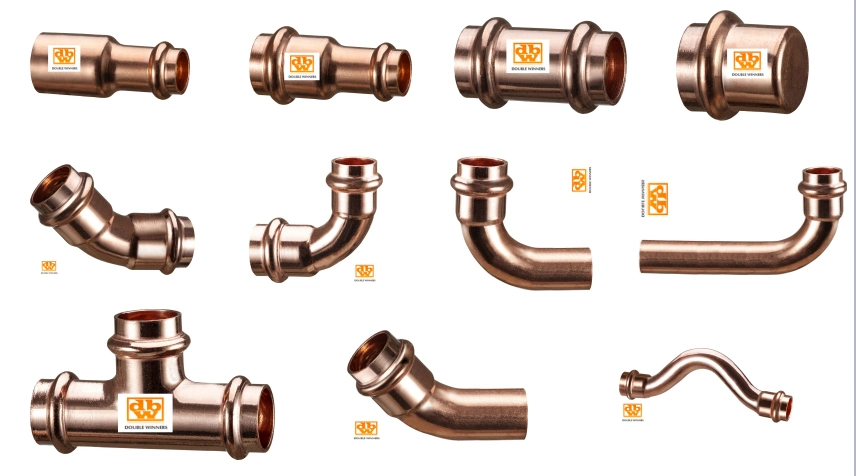

- For use with ASTM B 88 tubing

- Copper

-Press connection

- Components: EPDM sealing elements

-Available in sizes 1/2 " to 2 "

Model 9130

Features and benefits

Installation Instructions

FAQ

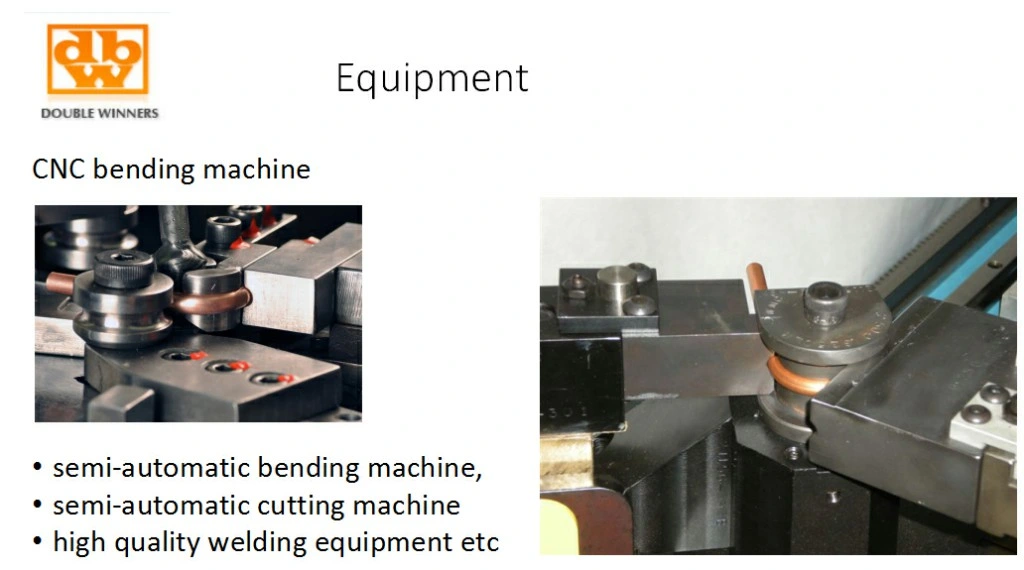

Company and production line view:

DBW copper press reducer

- For use with ASTM B 88 tubing

- Copper

-Press connection

- Components: EPDM sealing elements

-Available in sizes 1/2 " to 2 "

Model 9130

Features and benefits

The original copper press joining solution

Available in sizes 1/2" to 2", including elbows,couplings,tees,reducer, fitting reducer,caps,

Customizable with three sealing elements, EPDM, HNBR,FKM

leak detection feature identifies un-crimped connections

compatible with most common pressing tools and jaws in the market

All tubing must comply with the ASTM B88 standard

Operating parameters:

Operating pressure: 200PSI CWP max

Operating temperature range:-20°F-250°F

Approved applications

-Potable water

- Hydronic heating

-Chilled water

- Compressed air

-Non-medical gases

-Low pressure steam

Installation Instructions

- Cut tube square using a tube cutter or fine tooth saw

- Deburr tube ID using a deburring tool

- Deburr tube OD using half round file

- Check fittings bead to ensure seal is present. Do not use any type of oil lubrication

- Mark tube to proper fitting insertion depth( see insertion depth chart below)

| Fitting Insertion Depth Chart(1/2"-2") | ||||||

| Tube size | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

| Insertion Depth | 3/4" | 7/8" | 7/8" | 1" | 1-7/16" | 1-9/16" |

- Turn slightly while sliding press fitting onto tube. Slide all the way to insertion mark and make contact with stop

- Place press tool at a right angle over fitting bead .Start the pressing process. Please see specific tool manufacturer for tool instruction

FAQ

- What is the DBW press fittings system rated for regarding pressure and temperature?

- For what types of applications is the DBW system approved?

- For what types of media is the DBW systems designed?

- What products are included in DBW system offering?

- What does EPDM stand for?

Company and production line view: