Basic Info.

Product Description

BRASS ANGLE BALL VALVE WITH BUTTERFLY HANDLE

Product Description

Commodity Name: Butterfly Handle Brass Angle Ball Valve , water meter ball valve/lockable ball for water meter/Anti-theft Ball Valve ,Brass forged body, brass ball chrome plated,brass stem and brass handle.Full port, PTFE seals.

Material: Forged Brass ( CW617N, CW614 ,CW602N,ASTM C37700)

Size: 1/4'',3/8'',1/2'',3/4'',1'',11/4'',11/2'',2'',

Technical Specification:

Norminal pressure: 3.0Mpa

Tested Pressure: 2.0Mpa

Working medium: Water, oil, gas

Working temperature: -20° C≤ T≤ 120° C

Thread standard: According ISO228, ISO7/1, DIN2999/

For the handle, it could be changed to Zinc alloy and aluminum handle

Package details: Each valve by one polybag, inner box, Cartons with wooden pallets

Application: House connection and drinking meter networks, water pipe connection and flow control

| Product Name | Brass Ball Valve |

| Size | 1/4" - 2" |

| Material | Brass |

| Field of Application | Water |

| Working Pressure | MOP 5-20 |

| Guarantee Time | 3 Years |

| Work Temperature | -20°C + 120°C |

| Package | Standard export package or Customized |

| Payment | L/C,D/P,T/T,Western Union,Credit Card |

| Delivery | Ningbo Port,30 days after payment |

| Connection End | Female Thread |

Packaging & Shipping

Packing:

1). Bulk packing or small boxes packing in strong cartons then on pallets or plywood cases

2). Can be the same As per customer's request

3). Packages are strong enough to product

4). Packages are suitable for long time sea transportation and dampproof.

Shipping:

We select reputable shipping company to make shippment,to provide full and warmest serice.

Lead Time:

1) All of our will be arranged immediately after order confirmed or deposit received

2) We will do our best to delivery as quickly as possible as per different order.

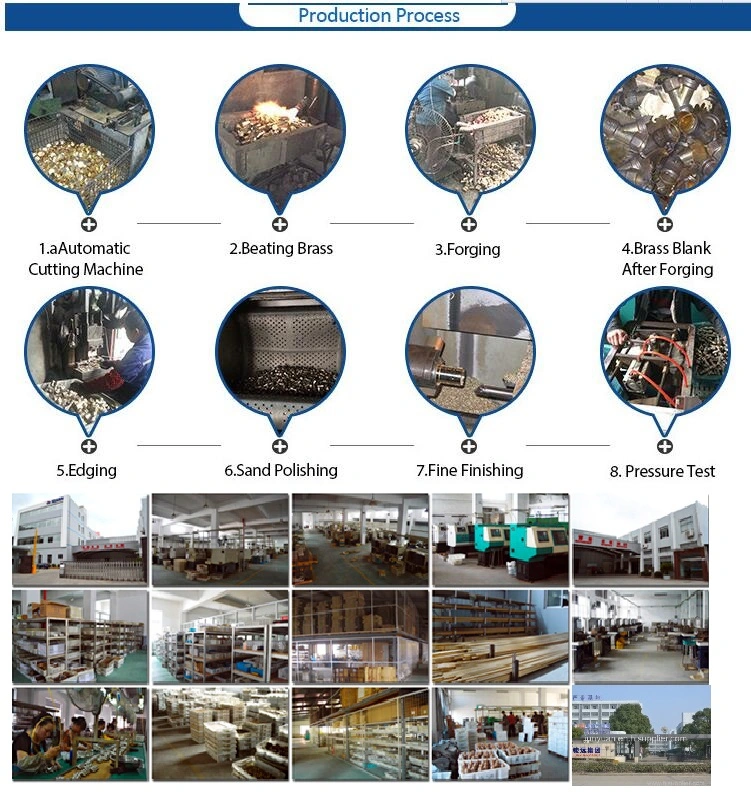

Machining Process

Why Choose US

We control the material of PTFE and stainless steel wires per customer's request.

Some are from Japan and Taiwan, some are from China local. Only choose high quality material.

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Contact to this supplier

http: xbvalve.en.made-in-china.com xbvalve.en.made-in-china.com