Basic Info.

Product Description

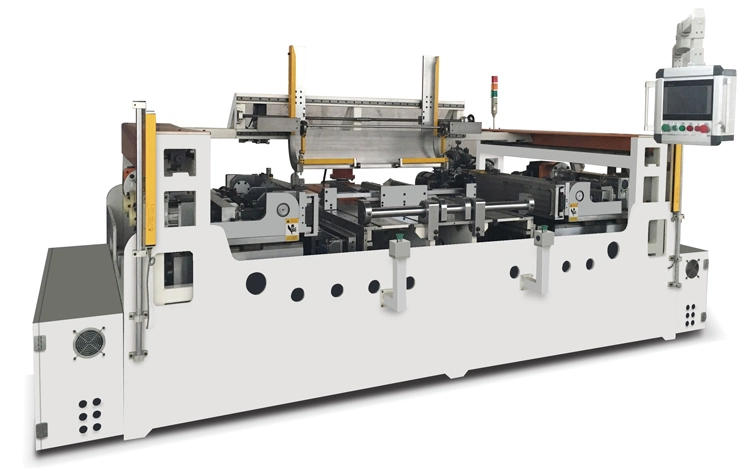

Machines for Manufacturing Aluminum Car Radiators

Aluminum radiators are becoming more and more popular than copper/brass car radiators.

We can provide complete car aluminum radiators making machines from A to Z:

No. | Name | Remarks |

1 | JG23-45A punching press | For making side plates & header plates |

2 | YHD-200 hydraulic press | For making side plates & header plates |

| 3 | Dies for side & header plates punching | Final price based on drawings |

| 4 | Ultrasonic cleaning machine | Cleaning side plates & header plates |

| 5 | Aluminum flat pipe high frequency welding machine | For flat tubes |

| 6 | Aluminum fin rolling machine | Normal speed |

| 7 | Fin rolling die | Based on fin drawing |

| 8 | Semi-automatic core builder | PZPJ-850ST |

| 9 | Toolings for core assembling |

|

| 10 | Continuous brazing oven 10m | Belt width based on max. Core width |

| 11 | Nitrogen gas tank | 15m3 |

| 12 | Core leakage tester (dry-type) | Leakage testing |

| 13 | Plastic water chamber clinching machine | Pneumatic or servo type |

Basically, if your budget is limited, you should have below basic machines:

1- Fin rolling machine

| Item | Data | |

| Blank material | Aluminum alloy foil | AA4343/AA3003/AA4343 or single foil |

| Foil thickness | 0.04~0.30mm | |

| Finished fin | Fin height | Based on rolling tool |

| Height tolerance | +0.03mm, - 0.01mm | |

| Fin height levelness | Less than 0.05mm | |

| Fin width | 8~200mm | |

| Fin pitch | 1.6~5.0mm | |

| Fin pitch tolerance | +/-0.10mm | |

| Machine capability | Foil feeding speed | 0-120m/min |

| Fin rolling speed | 1000-4000 corrugations per minute | |

| Fin cutting speed | Max. 60 times per minute | |

| Cutting tolerance | +/- 0 corrugation (on top of corrugation) | |

| Tooling | material | Forged high speed steel (W6) |

| Life | 250 million corrugations for laminated foil; 350 million corrugations for pure foil | |

| Total motor power | 5kW | |

| Compressed air source | 0.6MPa | |

| Machine dimension | About 6000 x 1500 x 2000mm | |

| Machine weight | About 2000kg | |

2- Core builder: There are various core builders in different configurations and automations, such as servo / pneumatic inserting header plates, servo / pneumatic compressing cores, manual / dispenser applying tubes, single-row, double-row or four-row, etc.

| Item | Data | |

| Distance between header plates | 350-850mm | |

| Distance between side plates | 150-750mm | |

| Thickness of built core | 16~48mm | |

| Core building precision | Core diagonal length error | ± 1.0mm |

| Core height error | ±1.0mm | |

| Core width error | ±1.5mm | |

| Clearance between fin and header plate | 2 +/-1mm | |

| Production speed (one cycle) | Less than 60s per core (based on operator's skill) | |

| Machine running cycle | Less than 40s | |

| Main die changing speed | Less than 30 minutes | |

| Air source | 0.6~0.8MPa | |

| Machine dimension | About 2100 x 1800 x 1750mm | |

3- Continuous brazing oven: detailed configuration will be based on your radiator core size and desired daily productivity.

4- Clinching machine: There are semi-automatic and full automatic model. Semi-automatic has two working stations, one station for crimping long edges of header plate and another station for crimping short edges of header plate. Movement between two stations are manual.

Full automatic clinching machine will crimp all four edges in one cycle, high efficiency.

| Item | Data |

| Suitable core width | 450-1100mm |

| Suitable header plate width | 30-140mm |

| Suitable header plate length | 200-1100mm |

| Clinching pitch | Adjustable, default 10mm |

| Clinching speed | 1-20 times per minute |

| Deformation of core and header plate after clinching | Less than 0.5mm |

| Clinching tool changeover time | Less than 10min (for another size tank) |

| Air source | 0.6MPa, 0.01m3/min |

| Machine dimension | About 2300 x 2200 x 1700mm |

| Machine weight | About 3200kg |

5- Leakage tester:

This tester is specially designed for testing air tightness of automotive radiator cores.

- Testing pressure range is 50~400KPa.

- Double-station testing can raise your efficiency well.

- Interface of tester is very clear; operation is very convenient, one key operation, automatic stopping.

- Very high testing precision, measurable leakage ≤1pa/s.

- Very large memory, 100,000 units testing data can be saved and reviewed.

| Item | Data | |

| Measuring range | 0.2~20mL/min | |

| Differential pressure | Min. resolution | 1Pa |

| Sensor withstand pressure | 2MPa | |

| Test pressure | Min. displaying | 1kPa |

| Displaying range | 0~400kPa | |

| Time setting | Filling, balancing, leakage checking, draining separately | |

| Power source | AC 220V ±5%, 50Hz | |

| Test source (dry clean air) | 0.6MPa | |

| Working ambient temperature | 0~40ºC | |

| Storage temperature | 0~50ºC | |

| RH | Less than 80%, without dew | |

Our Nantong Zhenhuan Trade Co., Ltd., established in 2004. is a private owned manufacturer and export agent of metal related fabricating & forming machinery.

Our products cover a full range of HVAC ventilation duct machines, transformer manufacturing related machines, motor making machines, lead-acid battery making machines, heat exchanger making machines, air-conditioner and refrigerator making machines, steel pipe forming & processing machines, tube/pipe fabricating & processing machines, steel tank making machines, steel wire bending machines, etc.

Focusing on international trade, we have placed our priority on both machine quality and service, which are the key elements that make your band more competitive in the global market. If you are looking for machines, components, OEM products, Zhenhuan Machines will be your most reliable partner.

We are ready to establish a long business relationship with your esteemed company as a supplier, a partner and a friend. We warmly welcome you from worldwide.