Basic Info.

Product Description

| https://youtu.be/XITAKxRV2h8 |

| https://youtu.be/4zSVChmhEeA |

| https://youtu.be/S8941LWQqjU |

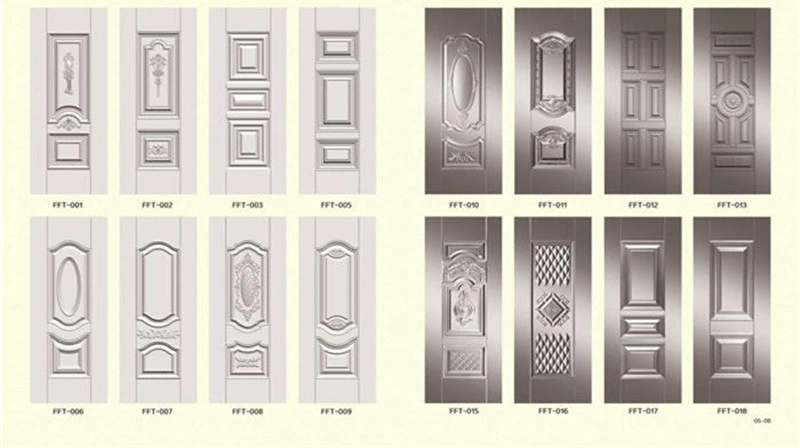

Door Steel Embossing machine, steel door making machine Iron security door emboss molding 2000 ton hydraulic press machine 500 Ton four column hydraulic press fitting machine, steel door embossing pressing machine stainless steel metal Doors embossing machine hydraulic press 2500ton

| Machine Body |

The slider uses rail guide; machine and slider are welded steel, the material is Q235-A, using carbon dioxide gas shielded arc welding, the weld should be ground smooth, no weld slag and

streaming scars, remove inner stress after weld. Columns guideway using high-quality materials, the guide portion after quenching hardness of HRC50 or more, good wear resistance.

Tope beam, worktable, left and right columns, sliders use Q235-A welded, remove inner stress after weld.

| Oil Cylinder |

material uniformity. Plunger rod surface hardening hardness is HRC45-50. The cylinder finishing by high-precision machine tools, cylinder bore after refining process to increase surface hardness and wear resistance,

so that the cylinder block has a high surface hardness, wear resistance and long service life.

Master cylinder seal ring using imported materials, to ensure reliable sealing.

| Hydraulic System |

provides high-pressure oil pressure and control the host. Hydraulic system arranged in the right of machine.

(1)Hydraulic system adopts advanced cartridge valve integrated system, the valve big flow, anti-pollution, flexible control, reliable performance, easy maintenance. Pilot solenoid valves are made of

high quality products.

(2)Hydraulic system working pressure is 25MPa, the main valve should be two-way cartridge valves. Hydraulic system is with overload protection devices. Hydraulic piping system

design reasonable, piping arranged in an orderly and tidy, high and low pressure pipeline is obvious

color distinction.

Hydraulic piping system should be reliable sealing flange connection priority connections, piping

layout and tidy, and the use

of shock and vibration-resistant gauge pipe clamps, pipe phosphate processing, and then coated

with rust-resistant paint.

(3)How to work Fixed stroke and fixed pressure; hydraulic machine operation: adjust, single cycle,

jog on the mold and work with automatic feeding.

(4)Fuel tank is divided into two parts, oil zone and oil back zone. Tank is steel plate welded structure,

which is installed with the oil level gauge, air filter, etc., tank was after pickling, passivation and anti-rust treatment, with separate oil filtration devices, and enables filtering device blockage accident alarm.

Tank with oil level indication and oil level gauge (upper and lower) alarm device.

(5)Filling valve Description: filling valve is to provide the master cylinder to draw or drain oil.

| Electric Control System |

Power requirements 380V/50HZ, three-phase.

(2)on the presses of various alarm signals, limit switch and press action to achieve interlock program.

(3)a centralized control panel on the layout of buttons and a necessary operation selector switch.

(4)with a move button station.

| Safety Protection System |

presses all the work stopped; press "stop" buttons, including motors are stopped.

(2)wo-hand operation button: hands downlink synchronization time 0.5 ~ 1S.

(3)the hydraulic circuit supporting Insurance: To prevent uncontrolled downward slide in the master

cylinder piston hydraulic bearing inferior vena setting interlock circuit, to ensure safety. Set hydraulic

interlock circuit safety valve to ensure that the support is not open, not on the master cylinder pressure chamber.

(4)overload protection: hydraulic system with hydraulic safety valve to ensure the press not overloaded work.

Technical parameter:

| Number | Item | Unit | Specifications | ||||

| 1 | Nominal force | KN | 25000 | ||||

| 2 | Max working pressure of liquid | MPa | 25 | ||||

| 3 | Oil cylinder max stroke | mm | 500 | ||||

| 4 | Max opening height | mm | 600 | ||||

| 5 | Return force | kn | 360 | ||||

| 6 | Work table effective area | L-R | mm | 1500 | |||

| F-B | mm | 2500 | |||||

| 7 | Slider speed | Fast down | mm/s | 45-50 | |||

| Slow down | mm/s | 8-12 | |||||

| Return | mm/s | 45-50 | |||||

| 8 | Main motor power | KW | 66 | ||||

About Prima Factory:

Nanjing Prima CNC Machinery Co., Ltd. is located in the center of China's machine tool industry, Mingjue Industrial Park , Shiqiu Town, Lishui Zone, Nanjing Our company specializes in Table type CNC Fiber Laser cutting machine, exchangeable table cnc fiber laser cutting machine, press brake, shearing machine , ironworker, punching machine , HVAC ducting machine and other metal forming forging equipment development and sales, our product positioning in the middle-top quality class. We commit a modern enterprise management methods, committed management and meticulous management and zero defect operation. Based on the quality of the product management, its excellent quality, innovative design, reasonable price, and improve after-sales service to win the majority of Chinese and foreign customers praise. Primapress Brand sheet metal processing equipment. Widely used in automobile manufacturing, communications, computers and so on. Prima CNC insist on leading technology strategy, positioning in the "do-class machine, a first-class brand," the high level of long-term sales of CNC machine tools in the process, not only to cultivate a number of series of numerical control products, while cultivating a group of skilled, practical style of high-quality workforce. Enterprises have their own research and development institutions, with the domestic strong product research and development of skills. Primapress specializes in the export business, our company already has CE certification and have one international after-sales team , Our machines are widely exported to Southeast Asia, EU, USA , South America, the Middle East and other markets around 100 nations with good quality, suitable price, comprehensive after-sales service, was widely welcomed by customers and unanimously approved. Our company ambition is "build quality brand, do excellent machine",it is also the company's entrepreneurial spirit and look forward to domestic and overseas friends to visit.

FAQ:

Q1. Trade company or manufacturer?

A: We manufacturer

Q2. Is it easy to operate for the new user ?

A: very easy

Q3. What should I do when the machine is in trouble?

A: Take photos and videos and contact our sales at once.

Q4: How long does it take to learn how to operate a laser cutting machine?

A: A couple of hours

Q5: Is it harmful to human body when in operation ?

A: no,very safe. Deep Drawing Hydraulic Press Machine 100ton 200ton 1000 Ton Price Steel Door Embossing Machine 2000t Hydraulic Door Press Machine 500 Ton four column hydraulic press fitting machine, steel door embossing pressing machine stainless steel metal Doors embossing machine hydraulic press 2500ton