Basic Info.

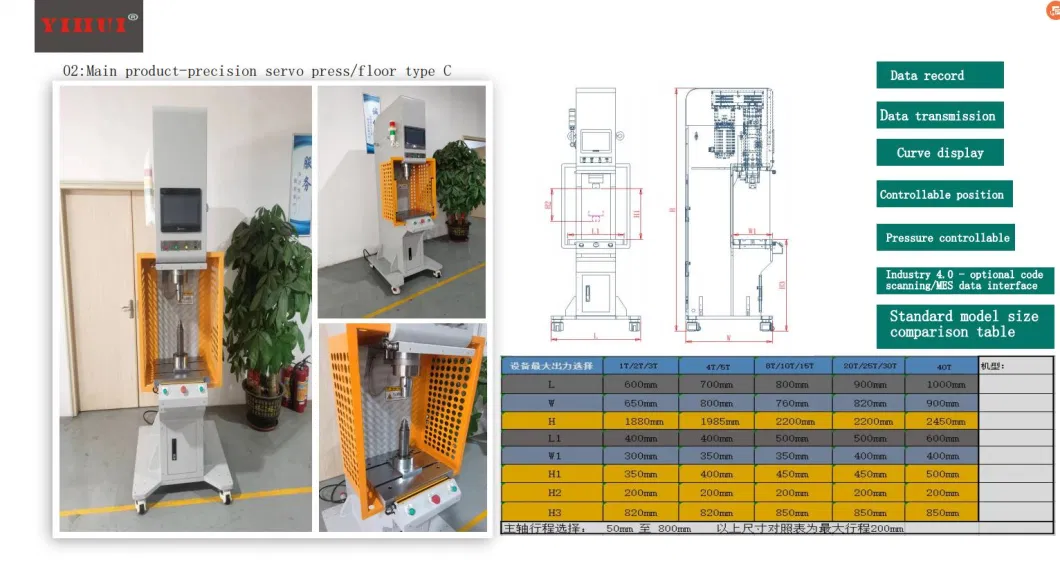

Product Description

Servo press-fit testing machine for automobile bearings

Product Application

1: Press-fitting of motor bearings

2: Press-fitting of the motor rotor

3: Press-fitting of automobile valve core

4: Press-fitting of motor shell

5: Press-fitting of automobile brake disc bearings

6: Press-fitting of motor gear

7: Press-fitting of bearing retainer for automobile direction assembly

8: Press-fitting of copper gaskets for automobile oil pipes

9: Press-fitting of automobile tubing head

Main Features

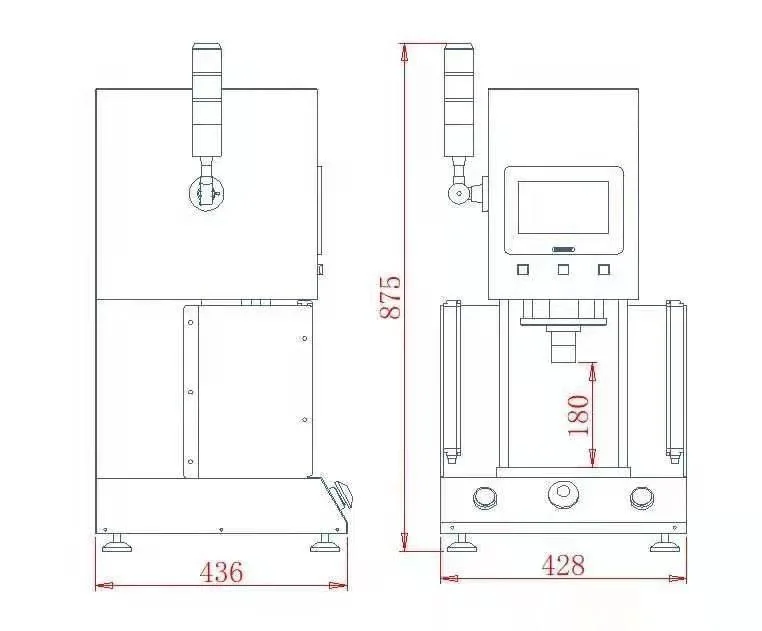

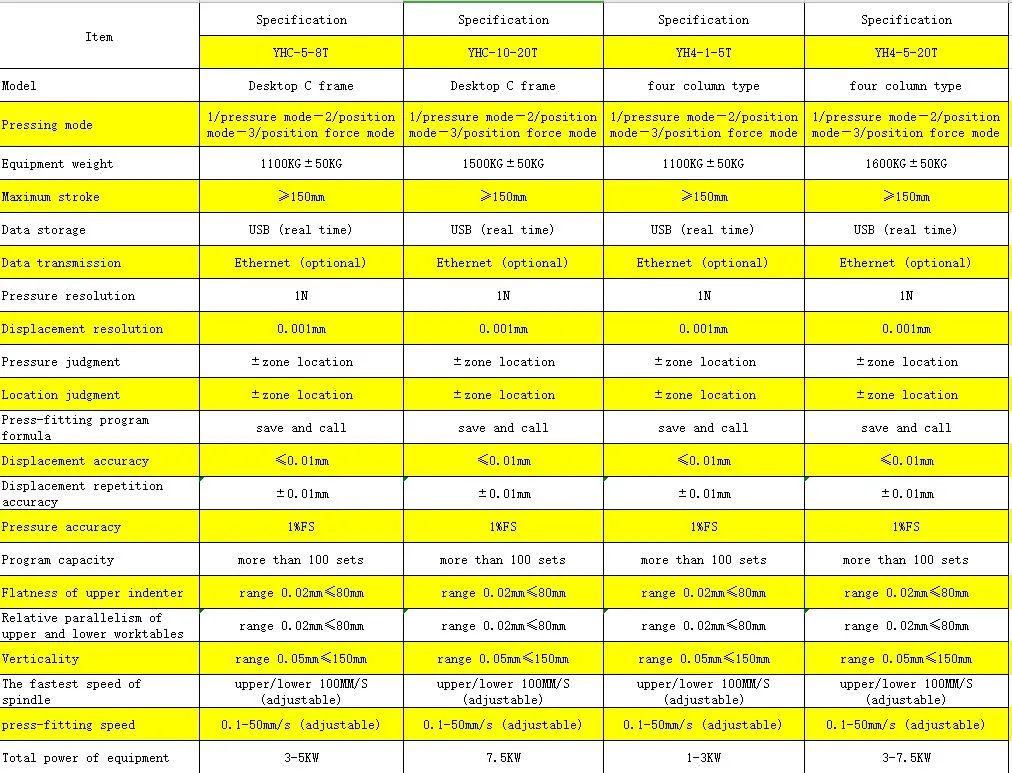

1. Position setting function: 1>Indenter position display, which can be set;

2>Press-fitting adjustable stroke: 0-150mm, controllable digital display actual press-fitting stroke,

3>Repeat accuracy: ±0.01mm;

2.Pressure setting function: 1>Display pressing pressure;

2>Set the upper limit of the pressure head pressure. When the press-fitting pressure is greater than the upper limit pressure, the upper pressure head immediately returns and alarms;

3>Set the lower limit of the pressure head pressure. When the press-fitting pressure is less than the lower limit pressure, the upper pressure head will return immediately and alarm;

4>Pressure display: 0-50000N, pressure curve real-time display.

5. It can store more than 100 sets of workpiece programs, which can be called at any time, and it has the function of parameter setting.

Certifications

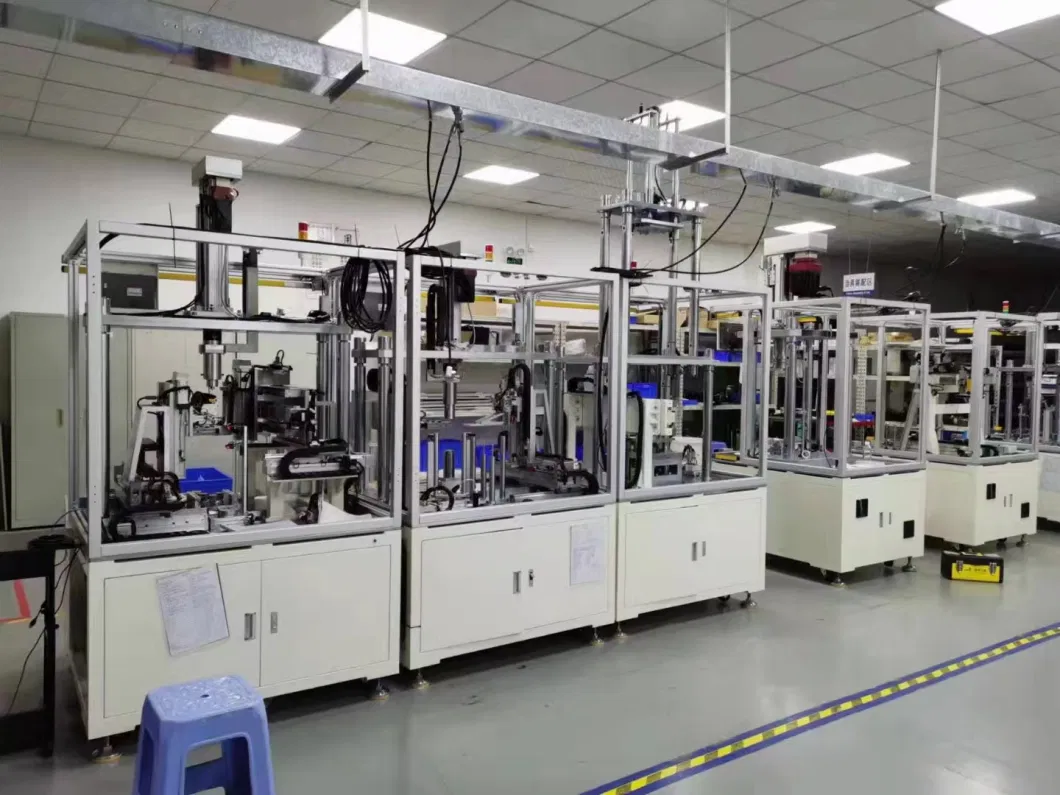

Our Factory

Dongguan Yihui Hydraulic Machinery Co., Ltd. is a company specializing in all kinds of standard and

non-standard hydraulic press,Servo electronic pressure mounting machine

and stamping machinery's design, manufacture, and sale.

YIHUI brand machines have been exported to over 60 pcs countries,

such as Germany,USA,UK,Sweden, Japan,Slovenia,Togo, Malaysia,Vietnam,Pakistan and so on.

YIHUI hydraulic press machines are widely applied to hardware,automotive,die casting,electronic,cookware,paper and many other industries.

YIHUI servo press widely applied to Press-fitting of motor bearings ,Press-fitting of the motor ,

Press-fitting of motor shell,Press-fitting of automobile brake disc bearings, Press-fitting of motor

gear,Press-fitting of bearing retainer for automobile direction assembly .

We are able to provide total solutions including machines,dies,product processing technology and automated production lines,etc.

Exhibition

Customers Show

why so famous brand company cooperate with us ?

1.Our factory have specialized in independent development and producing hydraulic press for 20 years.

So the product is stable and high quality.

2. Machine body, we use bending structure , much stronger than the common welding structure .

3. Oil pipe, we use Clip-on structure , much tight than common welding structure. Prevent oil leakage.

4. We take integrated oil manifold block, much easier to check machine and repair machine.

5.The main components are imported from Germany, Italy and Japan . So the quality is near the Japan production, but the unit price is lower than Japan production.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

All above specifications are standard sizes of hydraulic press machine.

Special customized specification is also available for us!