- Overview

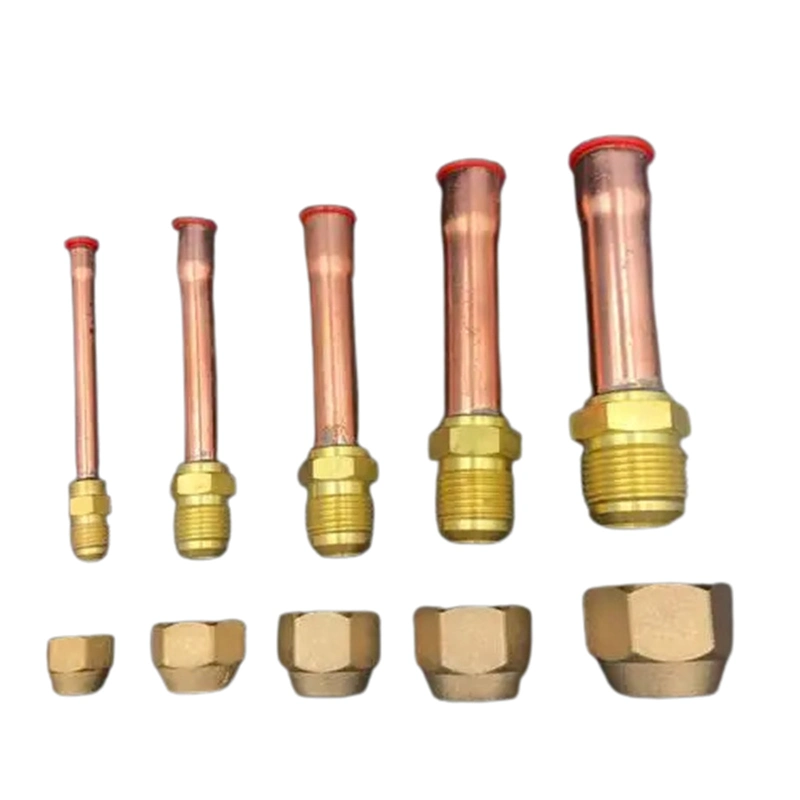

- Product Description

- Chemical Composition

- Certifications

- Production flow

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Product Description

| Product Name | Muller Mandev 8mm 40mm C10800 Copper Pipe for Bus Bars |

| Standard | ASTM, AISI, DIN, EN, GB, JIS, etc |

| Material | ASTM B75/B75M-2020: C10800 |

| MOQ | 300Kg |

| Package | Standard export package, suited for all kinds of transport, or as required. |

| price term | EXW, FOB, CFR, CIF, DDP, etc. |

| Contact | If you have any questions, please feel free to contact me. We are sure your inquiry or requirements will get prompt attention. |

| GRADE | TECHNOLOGY | TEMPER |

| COPPER | HOT ROLLED | M20 |

| COLD ROLLED | O60,H01,H02,H04,H06,H08 | |

| ITEM | SIZE | |

| PIPE/ TUBE | OUT DIAMETER | 1mm~300mm |

| WALL THICKNESS | 0.5mm~15mm | |

| LENGTH | 1000mm~3000mm, or as required | |

ASTM B75/75M-2020

Standard Specification for Seamless Copper Tube

This specification establishes the requirements for seamless round, rectangular, and square copper tube (UNS Nos. C10100, C10200, C10300, C10800, C12000, and C12200) suitable for general engineering applications. The material of manufacture shall be billets, cast bars, or tube. The tube shall be manufactured by hot- and cold-working processes, shall be cold drawn to the finished size and wall thickness, and shall be supplied in cold-drawn or annealed temper condition. The material shall conform to the chemical composition requirements prescribed for copper, phosphorus, as determined by chemical analysis, and to the mechanical property requirements including tensile strength, yield strength, Rockwell hardness, and straightening. Requirements for grain size, electrical mass resistivity, and dimensions are specified. The following test methods are detailed: grain size, electrical resistivity, tensile and yield strength, and hardness tests, expansion test for round table, microscopical examination, test for hydrogen embrittlement, and nondestructive tests such as electromagnetic (eddy-current), hydrostatic, and pneumatic pressure tests.

C10800 C10800 copper is a lightly alloyed grade of copper, formulated for primary forming into wrought products. C10800 is the UNS number for this material. Additionally, the AFNOR (French) designation is Cu-b2. It can have a moderately low tensile strength among the wrought coppers in the database. H80 C10800 copper is C10800 copper in the H80 (hard drawn) temper. It has the second highest strength and second lowest ductility compared to the other variants of C10800 copper.

Chemical Composition

| Copper UNS No. | Type of Copper |

C10100 | Oxygen-free electronic |

C10200 | Oxygen-free without residual deoxidants |

C10300 | Oxygen-free, extra low phosphorus |

| C10400 | Oxygen-free, silver bearing |

| C10500 | Oxygen-free, silver bearing |

| C10700 | Oxygen-free, silver bearing |

C10800 | Oxygen-free, low phosphorus |

| C11000 | Electrolytic tough pitch |

| C11300 | Silver-bearing tough pitch |

| C11400 | Silver-bearing tough pitch |

| C11600 | Silver-bearing tough pitch |

C12000 | Phosphorus deoxidized, low residual phosphorus |

C12200 | Phosphorus deoxidized, high residual phosphorus |

Copper Alloy

| Type | (GB) | (ISO) | (ASTM) | (EN) | (JIS) | (BS) | (DIN) |

| Red copper | TU2 | Cu-OF | C10100 | CW008A | C1011 | C101 | OF-Cu |

| T2 | Cu-FRHC | C11000 | C1100 | C101 | E-Cu58 | ||

| TP2 | Cu-DHP | C12200 | CW024A | C1220 | C106 | SF-Cu | |

| TP1 | Cu-DLP | C12000 | CW023A | C1201 | SW-Cu | ||

| Sliver copper | TAg0.1 | CuAg0.1 | C10400 | C1040 | CuAg0.1 | ||

| Brass | H90 | CuZn10 | C22000 | CW501L | C2200 | CZ101 | CuZn10 |

| H70 | CuZn30 | C26000 | CW505L | C2600 | CZ106 | CuZn30 | |

| H68 | C26200 | CW506L | C2620 | CuZn33 | |||

| H65 | CuZn35 | C27000 | CW507L | C2700 | CZ107 | CuZn36 | |

| H63 | CuZn37 | C27200 | CW508L | C2720 | CZ108 | CuZn37 | |

| H62 | CuZn40 | C28000 | CW509L | C2800 | CZ109 | ||

| Tin-Bronze copper | QSn4-0.3 | CuSn4 | C51100 | CW450K | C5111 | PB101 | CuSn4 |

| CuSn5 | C51000 | CW451K | C5101 | CuSn5 | |||

| QSn6.5-0.1 | CuSn6 | C51900 | CW452K | C5191 | PB103 | CuSn6 | |

| QSn8-0.3 | CuSn8 | C52100 | CW453K | C5210 | CuSn8 | ||

| QSn6.5-0.4 | |||||||

| Zn-white copper | BZn18-18 | CuNi18Zn20 | C75200 | CW409J | C7521 | NS106 | CuNi18Zn20 |

| BZn18-26 | CuNi18Zn27 | C77000 | CW410J | C7701 | NS107 | CuNi18Zn27 | |

| BZn15-20 | C7541 |

Typical Uses

General Characteristics | Applications |

| Good Electrical and Thermal Conductivity Good Electroplating Ability Good Corrosion Resistance Good Cold Forming and Deep Drawing Qualities Perfect Soldering and Welding Excellent Against Stress Corrosion Cracking | 1.Fluid pipe 2. Power Plant 3. Structure pipe 4. High and low-pressure Boiler tube 5. Seamless steel tubes for petroleum cracking 6. Conduit pipe 7. Scaffolding pipe pharmaceutical and ship building |

Certifications

Quality is an integral part of our Business Principles. The quality policy guides us to deliver products and services that exceed the customers' expectations and meet all the standards. These principles have helped us to get recognition as a trusted vendor from customers around the world. Maxi Metal Products are trusted and chosen by customers all over the world. This trust is based upon our quality certification and our reputation for consistently delivering high-quality products.

Who We Are?

Tianjin Zhongyantiancheng Steel Trading Co., Ltd

Customers Visiting

Q1:Can you send samples?

A: Of course, we can provide customers with samples and express shipping services all over the world.

Q2:What product information do I need to provide?

A: Please kindly provide the grade, width, thickness, surface treatment requirement should you have, and quantities you need to purchase.

Q3:It's my first time importing steel products, can you help me with it?

A: Sure, we have an agent to arrange the shipment, we will do it together with you.

Q4:How long does your delivery time take?

A: In general, our delivery time is within 7-15 days and may be longer if the quantity is extremely large or special circumstances occur.

Q5: How many countries have you already exported to?

A: We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana, Somalia, and other African countries. Our export experience is rich, we are familiar with different market demands, can help customers avoid a lot of trouble.

Q6:Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory.

Q7:Does the product have a quality inspection before loading?

A: Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.