Basic Info.

Model NO.

XAGZ64/1000-30U

Condition

New

Plate Number

45PCS

Plate Size

1000*1000mm

Cloth Number

44PCS

Handle

Automatic Type

Volume of Chamber

0.85m3

Filtration Area

64 M²

Filtration Capacity

960L

Dimension

4680*1500*3200mm

Transport Package

International Standard Packaging

Specification

hydraulic press

Trademark

LEABON

Origin

Henan, China

HS Code

8421291090

Production Capacity

20sets/Month

Product Description

Gold Tailings PLC Control High Pressure Membrane Filter Press

Description:

Filter press can be divided into frame filter press and recessed filter press.It is a kind fo pressure filtration equipment for intermittent operation,being appalicable in any solid-liquid seperation for suspengding liquid.It depends on compaction device to press filter press then push the suspending liquid into chamber room by the pump, the filtration cloth can separate the solid and liquid material.It has the feature of simple structure,good separating effect,convenient operation,wide range of application.It is widely used in fields of coal washing, alchol,petroleum, chemical industry, dyeing ,metallurgy, medicine,food,textile, industrial sewage and urban domestic sewage treatment.Our company manufactures all kinds of recessed and frame mechanical filter press,hydraulic filter press, membrane filter press,full auto filter press and quick opening filter press as well as fittings.

Main parameters:

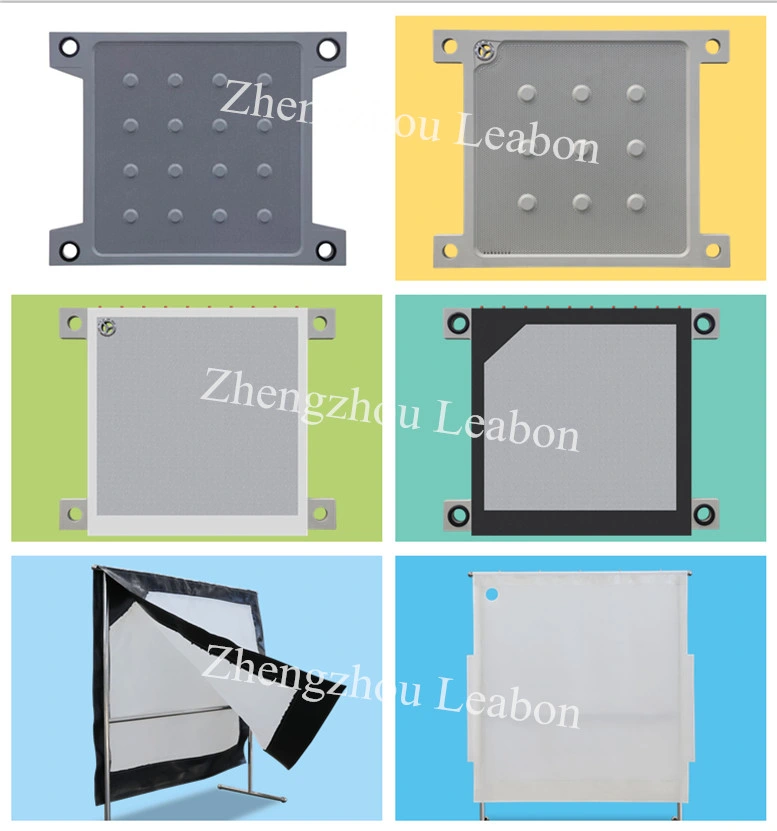

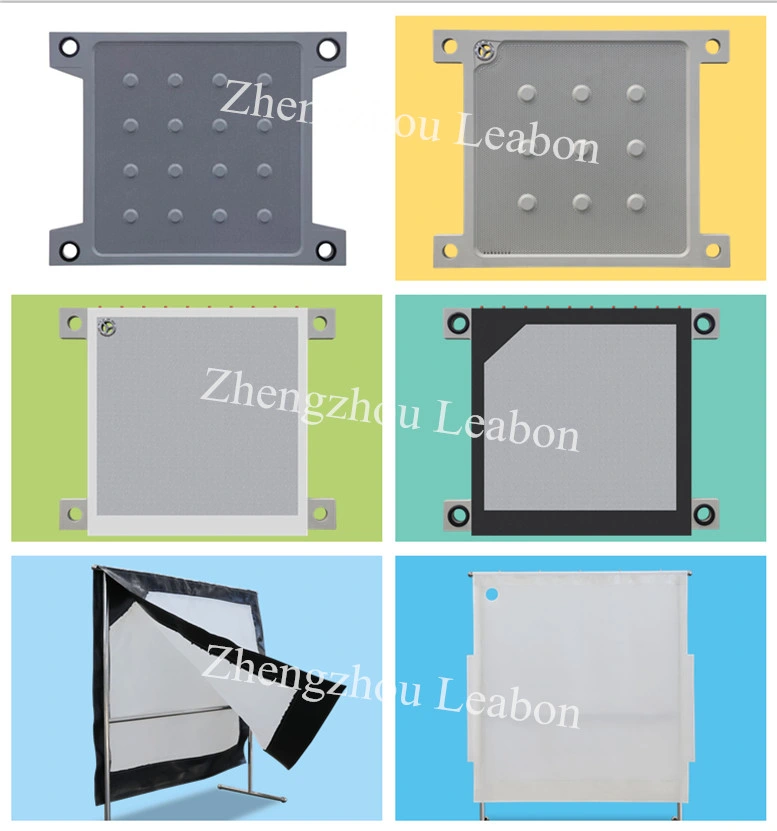

Filter Press Plate :

Product advantages

1. Started research and development and testing in 2011, and put it into the market in 2014.

2, the sealing effect is good.

3. Loading and unloading filter cloth is convenient and safe.

4, reduce the water content, blowing 100% through the filter cake, no wind leakage phenomenon (copper concentrate, gold concentrate and other colored concentrate filter cake moisture content is less than 8%, in other industries under the same conditions, the water content decreased by 6% - 12%), the filter cake automatically falls off, reducing the overall operating costs.

5, the feed is even, there will be no uneven thickness of the filter cake.

6, washing thoroughly and thoroughly, can save 30% -50% of water.

7. The backflushing pipeline and the feeding pipeline are clean without residual slurry, and the service life of the backflushing valve is more than doubled.

8. Compared with the filter plate of the same type, the filtration area is increased by 13%.

Factory and Workshop:

Application:

1. Gold Smelter

For high sulfur gold concentrate

Two sets of 2000 type 700 square single chamber feed filter presses were used, each cycle was 40 minutes, and the filter cake moisture was 8-9%.

2. For low sulfur gold tailings

Three sets of 2000 type 700 square single chamber feed filter presses were used, each cycle was 50 minutes, and the filter cake moisture was 15-16%.

3. Used for gold tailings burning sulfur red slag

A 2000 type 500 square single chamber feed filter press is used, each cycle is 50 minutes, and the filter cake moisture is 15-16%.

Our Service

Description:

Filter press can be divided into frame filter press and recessed filter press.It is a kind fo pressure filtration equipment for intermittent operation,being appalicable in any solid-liquid seperation for suspengding liquid.It depends on compaction device to press filter press then push the suspending liquid into chamber room by the pump, the filtration cloth can separate the solid and liquid material.It has the feature of simple structure,good separating effect,convenient operation,wide range of application.It is widely used in fields of coal washing, alchol,petroleum, chemical industry, dyeing ,metallurgy, medicine,food,textile, industrial sewage and urban domestic sewage treatment.Our company manufactures all kinds of recessed and frame mechanical filter press,hydraulic filter press, membrane filter press,full auto filter press and quick opening filter press as well as fittings.

Main parameters:

| Model | Filter area m2 | Palte size mm | Cake thickness mm | Filter plate number pcs | Cubage of filter chamber (L) | Filter pressure (Mpa) | Foundation dimension | dimension | Weight Kg | ||||

| L1 mm | B mm | C mm | Length mm | width mm | High mm | ||||||||

| BMS/ 390-25U | 1 | 390*390 | 25 | 4 | 13 | 0.5 | 650 | 150 | 500 | 1150 | 760 | 650 | 410 |

| 2 | 9 | 25 | 900 | 1450 | 570 | ||||||||

| 3 | 14 | 38 | 1150 | 1695 | 740 | ||||||||

| BMS/ 30U | 1 | 390*390 | 30 | 4 | 15 | 0.5 | 710 | 150 | 500 | 1210 | 760 | 650 | 350 |

| 2 | 9 | 31 | 1020 | 1565 | 400 | ||||||||

| 3 | 14 | 46 | 1330 | 1875 | 455 | ||||||||

| XMSQ/ 520-20U | 4 | 520*520 | 20 | 9 | 40 | 0.5-1.5 | 1130 | 200 | 600 | 1730 | 830 | 850 | 560 |

| 6 | 14 | 60 | 1360 | 1960 | 630 | ||||||||

| 8 | 19 | 80 | 1580 | 2180 | 700 | ||||||||

| 12 | 29 | 120 | 2060 | 2660 | 830 | ||||||||

| 16 | 39 | 160 | 2460 | 3050 | 980 | ||||||||

| 18 | 44 | 176 | 2690 | 3260 | 1160 | ||||||||

| 20 | 49 | 200 | 2910 | 3500 | 1360 | ||||||||

| BNSQ/ 520-30U | 4 | 520*520 | 30 | 9 | 60 | 0.5 | 1300 | 200 | 600 | 1900 | 830 | 850 | 590 |

| 6 | 14 | 90 | 1600 | 2200 | 660 | ||||||||

| 8 | 19 | 120 | 1900 | 2500 | 760 | ||||||||

| 12 | 19 | 180 | 2520 | 3120 | 930 | ||||||||

| 16 | 39 | 240 | 3060 | 3660 | 1100 | ||||||||

| XMSQ/ 700-25U | 20 | 700*700 | 25 | 24 | 250 | 0.5-1.6 | 2200 | 460 | 800 | 3100 | 950 | 11000 | 2210 |

| 30 | 37 | 380 | 2880 | 3800 | 2660 | ||||||||

| 40 | 49 | 500 | 3500 | 4400 | 3080 | ||||||||

| BNSQ/ 700-30U | 20 | 700*700 | 30 | 24 | 300 | 0.5 | 2450 | 460 | 800 | 3350 | 950 | 1100 | 2300 |

| 30 | 37 | 450 | 3230 | 4050 | 2800 | ||||||||

| 40 | 49 | 600 | 3950 | 4900 | 3500 | ||||||||

Filter Press Plate :

Product advantages

1. Started research and development and testing in 2011, and put it into the market in 2014.

2, the sealing effect is good.

3. Loading and unloading filter cloth is convenient and safe.

4, reduce the water content, blowing 100% through the filter cake, no wind leakage phenomenon (copper concentrate, gold concentrate and other colored concentrate filter cake moisture content is less than 8%, in other industries under the same conditions, the water content decreased by 6% - 12%), the filter cake automatically falls off, reducing the overall operating costs.

5, the feed is even, there will be no uneven thickness of the filter cake.

6, washing thoroughly and thoroughly, can save 30% -50% of water.

7. The backflushing pipeline and the feeding pipeline are clean without residual slurry, and the service life of the backflushing valve is more than doubled.

8. Compared with the filter plate of the same type, the filtration area is increased by 13%.

Factory and Workshop:

Application:

1. Gold Smelter

For high sulfur gold concentrate

Two sets of 2000 type 700 square single chamber feed filter presses were used, each cycle was 40 minutes, and the filter cake moisture was 8-9%.

2. For low sulfur gold tailings

Three sets of 2000 type 700 square single chamber feed filter presses were used, each cycle was 50 minutes, and the filter cake moisture was 15-16%.

3. Used for gold tailings burning sulfur red slag

A 2000 type 500 square single chamber feed filter press is used, each cycle is 50 minutes, and the filter cake moisture is 15-16%.

Our Service

1. supply the free material testing in laboratory and give out the report for free.

2. supply free model selection according to your capacity and other information.

3. supply manual operation to insturct the operation.

4. supply installation instruction.

5. supply full set of filtration solution . We have top pump , valve , motor agreement supplier , can give you turnkey service.