- Overview

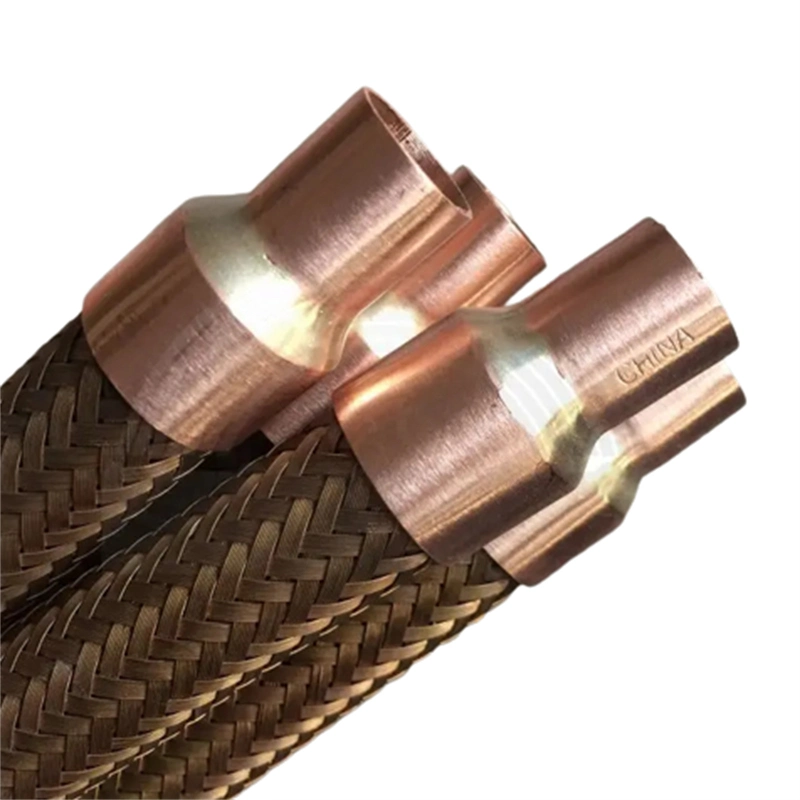

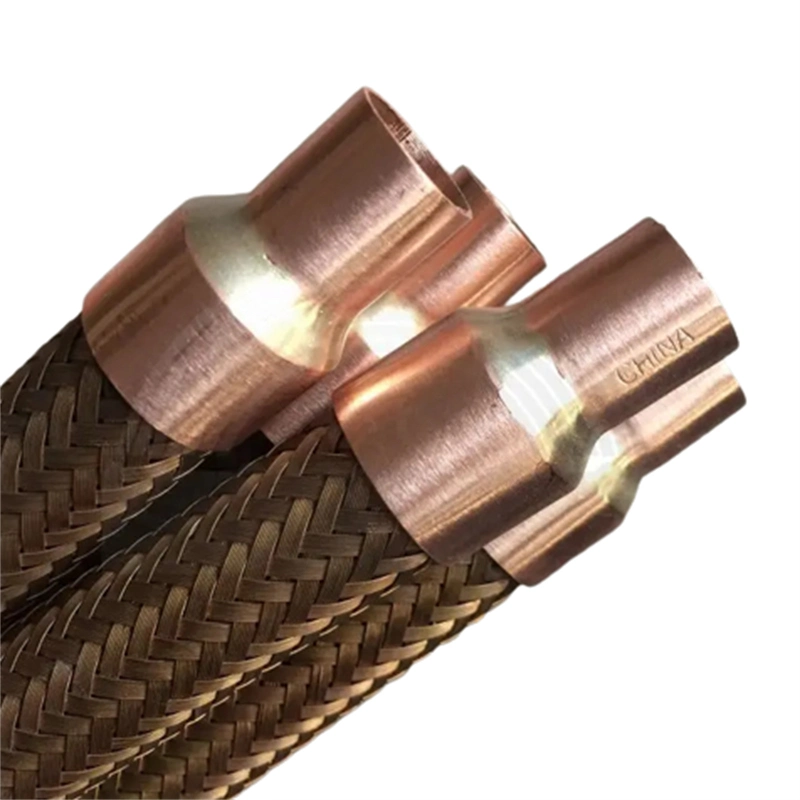

- Product Description

- Chemical Composition

- Certifications

- Production flow

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Model NO.

C33000

Temper

Soft Anneal, Deep-Drawing Anneal, etc

Surfaces

Mill, Polished, Bright, Oiled, Hair Line,etc

Standards

ASTM, GB, ISO, DIN, BS, JIS, En, etc.

Diameter

<500mm, or as Requirement

Length

<3m, or as Requirement

Thickness

1mm~15mm, or as Requirment

Transport Package

Bundles or as Customer′s Requirement

Trademark

ZYTC

Origin

China

HS Code

7409119000

Production Capacity

200tons/Month

Product Description

ca

ASTM B135/135M-2017Standard Specification for Seamless Brass Tube

C33000

UNS C33000 is an alloy composed primarily of copper and zinc. The alloy typically contains around 60-70% copper and 30-40% zinc, creating a strong and durable material with excellent wear and superior corrosion resistance. Other trace elements may also be added to enhance certain properties, such as heat resistance or machinability.

The chemical composition of UNS C33000 provides it with excellent corrosion resistance as well as superior mechanical properties, including high tensile strength and ductility.

In addition, this alloy has good heat resistance, allowing it to maintain its strength even under high temperatures. Its physical properties make it an ideal choice for various applications such as valves, pumps, fasteners, electrical components, fittings, and more.

Production Flow

Production Flow

Packaging & Shipping

| Product Name | Crimping Leaking Connecting Type L Brass Pipe to PVC Adapter |

| Standard | ASTM, AISI, DIN, EN, GB, JIS, etc |

| Material | ASTM B135/B135M-2017: C33000 |

| MOQ | 300Kg |

| Package | Standard export package, suited for all kinds of transport, or as required. |

| price term | EXW, FOB, CFR, CIF, DDP, etc. |

| Contact | If you have any questions, please feel free to contact me. We are sure your inquiry or requirements will get prompt attention. |

| GRADE | TECHNOLOGY | TEMPER |

| COPPER | HOT ROLLED | M20 |

| COLD ROLLED | O60,H01,H02,H04,H06,H08 | |

| ITEM | SIZE | |

| PIPE/ TUBE | OUT DIAMETER | 1mm~300mm |

| WALL THICKNESS | 0.5mm~15mm | |

| LENGTH | 1000mm~3000mm, or as required | |

ASTM B135/135M-2017

Standard Specification for Seamless Brass Tube

This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. The following copper alloys are specified and classified according to their nominal compositions: UNS No. C22000, UNS No. C23000, UNS No. C26000, UNS No. C27000, UNS No. C27200, UNS No. C27400, UNS No. C28000, UNS No. C33000, UNS No. C33200, UNS No. C37000, and UNS No. C44300. The tempers of drawn tube shall be designated as light-drawn (H55), drawn (H58), and hard-drawn (H80). Light-drawn (bending) temper is used only when a tube of some stiffness but yet capable of being bent is needed. Drawn temper is for general purposes and is most commonly used where there is no specific requirement for high strength on the one hand or for bending qualities on the other. Hard-drawn temper is used only where there is need for a tube as strong as is commercially feasible for the sizes indicated. For any combination of diameter and wall thickness not covered under hard-drawn temper, the values given for drawn temper shall be used. The tempers of annealed tube shall be designated as light anneal (O50) and soft anneal (O60). The tubes shall undergo mechanical tests such as tension test, Rockwell hardness test, and expansion test in order to determine certain properties such as tensile strength and hardness. A nitrate test shall be done to detect and remove vapor. Nondestructive tests such as eddy-current test, hydrostatic test, and pneumatic test shall be done as well.

C33000 UNS C33000 is an alloy composed primarily of copper and zinc. The alloy typically contains around 60-70% copper and 30-40% zinc, creating a strong and durable material with excellent wear and superior corrosion resistance. Other trace elements may also be added to enhance certain properties, such as heat resistance or machinability.

The chemical composition of UNS C33000 provides it with excellent corrosion resistance as well as superior mechanical properties, including high tensile strength and ductility.

In addition, this alloy has good heat resistance, allowing it to maintain its strength even under high temperatures. Its physical properties make it an ideal choice for various applications such as valves, pumps, fasteners, electrical components, fittings, and more.

UNS C33000 is an alloy composed primarily of copper and zinc that offers a combination of desirable physical properties. With high ductility and strength, as well as good wear resistance, Brass C33000 is often used in products such as valves, marine hardware, pump parts and musical instrument components, to name a few. Its natural patina enhances its corrosion resistance, meaning it will not corrode or wear away quickly over time. In addition to its mechanical properties, Brass C33000 has excellent wearability and plating qualities. This makes it a great choice for electrical applications where good contact between two surfaces needs reliable conductivity.

Chemical Composition

| Copper Alloy UNS No.2 | Previously Designation | Nominal Composition, % | |||

Copper | Zinc | Lead | Tin | ||

| C22000 | 7 | 90 | 10 | ... | ... |

| C23000 | 1 | 85 | 15 | ... | ... |

| C26000 | 2 | 70 | 30 | ... | ... |

| C27000 | 9 | 65 | 35 | ... | ... |

| C27200 | 8 | 63 | 37 | ... | ... |

| C27400 | ... | 62.5 | 37.5 | ... | ... |

| C28000 | 5 | 60 | 40 | ... | ... |

| C33000 | 3 | 66 | 33.5 | 0.5 | ... |

| C33200 | 4 | 66 | 32.4 | 1.6 | ... |

| C37000 | 6 | 60 | 39 | 1 | ... |

| C44300 | ... | 71.5 | 27.5 | ... | 1 |

Copper Alloy

| Type | (GB) | (ISO) | (ASTM) | (EN) | (JIS) | (BS) | (DIN) |

| Red copper | TU2 | Cu-OF | C10100 | CW008A | C1011 | C101 | OF-Cu |

| T2 | Cu-FRHC | C11000 | C1100 | C101 | E-Cu58 | ||

| TP2 | Cu-DHP | C12200 | CW024A | C1220 | C106 | SF-Cu | |

| TP1 | Cu-DLP | C12000 | CW023A | C1201 | SW-Cu | ||

| Sliver copper | TAg0.1 | CuAg0.1 | C10400 | C1040 | CuAg0.1 | ||

| Brass | H90 | CuZn10 | C22000 | CW501L | C2200 | CZ101 | CuZn10 |

| H70 | CuZn30 | C26000 | CW505L | C2600 | CZ106 | CuZn30 | |

| H68 | C26200 | CW506L | C2620 | CuZn33 | |||

| H65 | CuZn35 | C27000 | CW507L | C2700 | CZ107 | CuZn36 | |

| H63 | CuZn37 | C27200 | CW508L | C2720 | CZ108 | CuZn37 | |

| H62 | CuZn40 | C28000 | CW509L | C2800 | CZ109 | ||

| Tin-Bronze copper | QSn4-0.3 | CuSn4 | C51100 | CW450K | C5111 | PB101 | CuSn4 |

| CuSn5 | C51000 | CW451K | C5101 | CuSn5 | |||

| QSn6.5-0.1 | CuSn6 | C51900 | CW452K | C5191 | PB103 | CuSn6 | |

| QSn8-0.3 | CuSn8 | C52100 | CW453K | C5210 | CuSn8 | ||

| QSn6.5-0.4 | |||||||

| Zn-white copper | BZn18-18 | CuNi18Zn20 | C75200 | CW409J | C7521 | NS106 | CuNi18Zn20 |

| BZn18-26 | CuNi18Zn27 | C77000 | CW410J | C7701 | NS107 | CuNi18Zn27 | |

| BZn15-20 | C7541 |

Typical Uses

General Characteristics | Applications |

| Good Electrical and Thermal Conductivity Good Electroplating Ability Good Corrosion Resistance Good Cold Forming and Deep Drawing Qualities Perfect Soldering and Welding Excellent Against Stress Corrosion Cracking | 1.Fluid pipe 2. Power Plant 3. Structure pipe 4. High and low-pressure Boiler tube 5. Seamless steel tubes for petroleum cracking 6. Conduit pipe 7. Scaffolding pipe pharmaceutical and ship building |

Certifications

Quality is an integral part of our Business Principles. The quality policy guides us to deliver products and services that exceed the customers' expectations and meet all the standards. These principles have helped us to get recognition as a trusted vendor from customers around the world. Maxi Metal Products are trusted and chosen by customers all over the world. This trust is based upon our quality certification and our reputation for consistently delivering high-quality products.

Who We Are?

Tianjin Zhongyantiancheng Steel Trading Co., Ltd

Tianjin Zhongyantiancheng Steel Trading Co., Ltd is the leader in the sale and distribution of aluminum, copper, copper alloys, brass, and bronze. We maintain huge inventories of aluminum, copper, brass, bronze, and specialty copper alloys. Our production and inventories consist of plates, coils, strips, foils, bars, tubes, rounds, hollows, rectangles, squares, hexagons, wires, and made-to-order shapes for customer-specific applications. We are the leading China alloy distributor of over one hundred different grades of aluminum and copper alloys in excess of 5000 metric tons.

Customers Visiting

Customers Visiting

FAQ

Q1:Can you send samples?

A: Of course, we can provide customers with samples and express shipping services all over the world.

Q2:What product information do I need to provide?

A: Please kindly provide the grade, width, thickness, surface treatment requirement should you have, and quantities you need to purchase.

Q3:It's my first time importing steel products, can you help me with it?

A: Sure, we have an agent to arrange the shipment, we will do it together with you.

Q4:How long does your delivery time take?

A: In general, our delivery time is within 7-15 days and may be longer if the quantity is extremely large or special circumstances occur.

Q5: How many countries have you already exported to?

A: We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana, Somalia, and other African countries. Our export experience is rich, we are familiar with different market demands, can help customers avoid a lot of trouble.

Q6:Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory.

Q7:Does the product have a quality inspection before loading?

A: Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q1:Can you send samples?

A: Of course, we can provide customers with samples and express shipping services all over the world.

Q2:What product information do I need to provide?

A: Please kindly provide the grade, width, thickness, surface treatment requirement should you have, and quantities you need to purchase.

Q3:It's my first time importing steel products, can you help me with it?

A: Sure, we have an agent to arrange the shipment, we will do it together with you.

Q4:How long does your delivery time take?

A: In general, our delivery time is within 7-15 days and may be longer if the quantity is extremely large or special circumstances occur.

Q5: How many countries have you already exported to?

A: We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana, Somalia, and other African countries. Our export experience is rich, we are familiar with different market demands, can help customers avoid a lot of trouble.

Q6:Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory.

Q7:Does the product have a quality inspection before loading?

A: Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.