- Overview

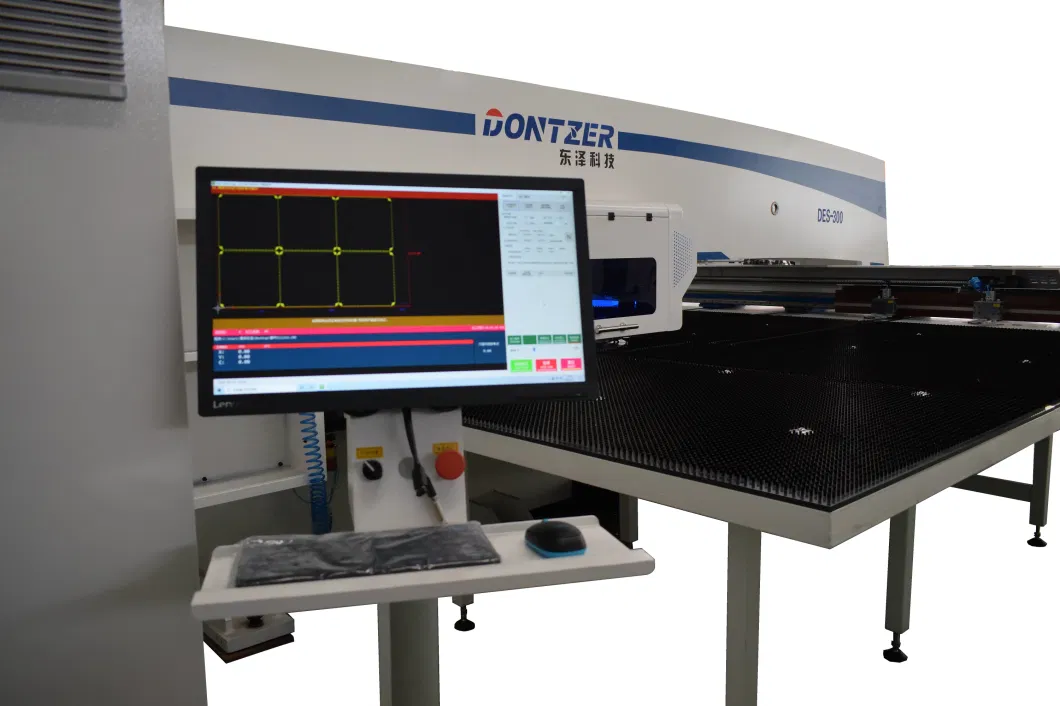

- Detailed Photos

- Punching Model

- Product Parameters

- Product category

- Company Profile

- FAQ

Basic Info.

Model NO.

DES-300

Controlling Mode

CNC

Automatic Grade

Automatic

Power Source

Mechanical Drive

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Punch Force

30 Kn

Max. Processing Sheet

2500* 1500 mm

Max. Processing Sheet Thickness

6.35 mm

Max. Punch Diameter

88.9 mm

Accuracy

±0.1 mm

Servo Unit

Panasonic, Synmot, Sano

Loading

20ot, 40gp Container

Package

Foam and Plastic Film, Customized

Color

Blue, or Customized

Linear Guide and Ball Screw System

Japan NSK/ Tsubaki, Taiwan Hiwin/Tbi

Transport Package

Pallet, Foam and Plastic Film

Specification

5500*5200*2280 MM

Trademark

AYPA

Origin

China

HS Code

8462111000

Production Capacity

200 Sets/Year

Product Description

China Factory Punching Plate Pipe Servo Turret Punch Press for Stainess Steel, Copper, Aluminum Blinds,Shutters, Shades, Cabinet

* Steel plate frame

* Tempering fireplace

* One-step clamping

* Tempering fireplace

* One-step clamping

* Thick rotating tower

* Extending mold life

* High accuracy

* Extending mold life

* High accuracy

* International standard 85 series mould

* High surface hardness

* Strong anti-abrasion

* High surface hardness

* Strong anti-abrasion

* Tempering clamp slide

* Blackening of clamp surface

* Installing scales

* Blackening of clamp surface

* Installing scales

| ITEMS | UNIT | SPECIFICATIONS |

| Punch Force | KN | 30 |

| Frame Structure | / | O type |

| Max. Processing Sheet (Reposition) | MM | 2500* 1250 |

| No. Of Clamp | NO. | 3 |

| Max. Processing Sheet Thickness | MM | 6.35 |

| Max. Punch Diameter | MM | Φ88.9 |

| Punch Pace | HPM | 1800 |

| Max. Punch Hit at 1mm Pace | HPM | 800 |

| Max. Punch Hot at 25.4mm Pace | HPM | 400 |

| No. Of Tool Station | No. | 16/24/32, including A,B,C,D station set |

| Controlling Axis | N0. | 5 (X/Y/R/T/C) |

| Mould Structure | / | International Standard Mould |

| Main Motor | / | Japan Panasonic |

| Reposition Cylinder | Set | 2 |

| Max. Steel Moving Speed | M/min | 106 |

| Tooling Rotation Speed | Rpm | 30 |

| Accuracy | mm | ±0.1 |

| Max. Load Weight | Kg | 156 |

| Air Pressure | MPa | 0.6 |

| Power | V | 380± 5% |

| Total Weight | T | 14 |

| Outline Dimension | mm | 5200* 5200*2280 |

1. How about the delivery time?

Generally it's 15-30 days based on the model.

2. How is the warranty time?

1 year after installation.

Lifetime free technical support.

3. How to choose the suitable machine?

Please advise us the material/ thickness/ dimension of metal sheet, and the punched drawing.