Basic Info.

Model NO.

917

Controlling Mode

CNC

Automatic Grade

Automatic

Power Source

Mechanical Drive

Precision

High Precision

Certification

CE

Condition

New

Transport Package

Wooden Package

Specification

17500kg

HS Code

8462411100

Production Capacity

50 Sets/Year

Product Description

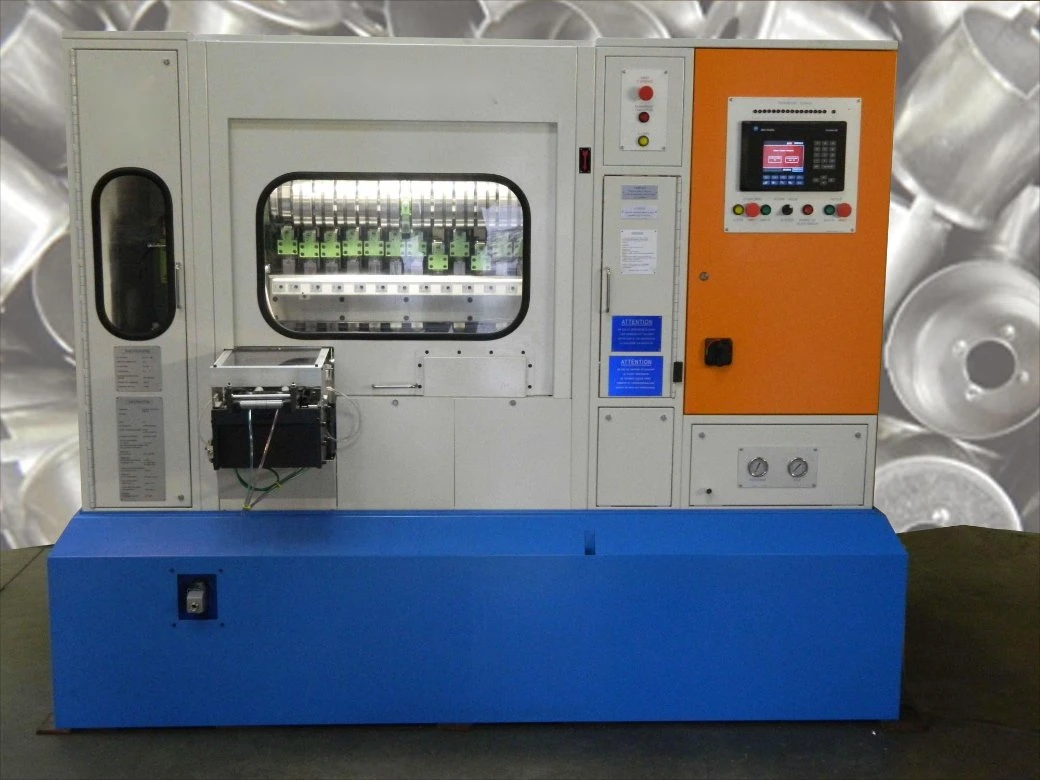

Cam Press Model 917

Technical specifications

Machine 917

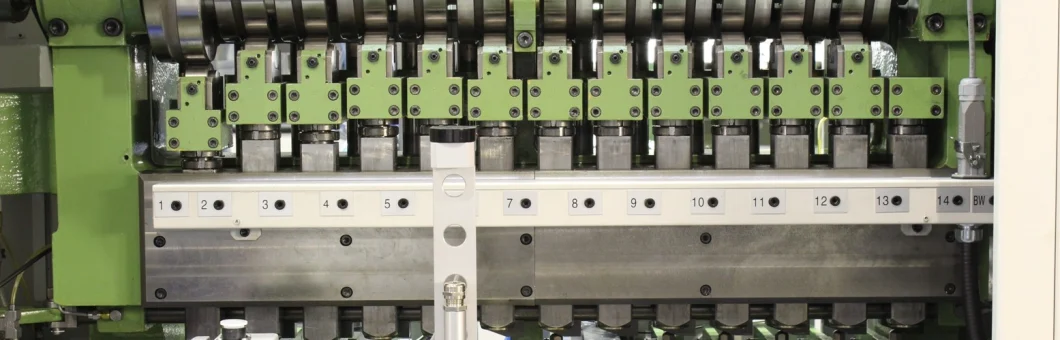

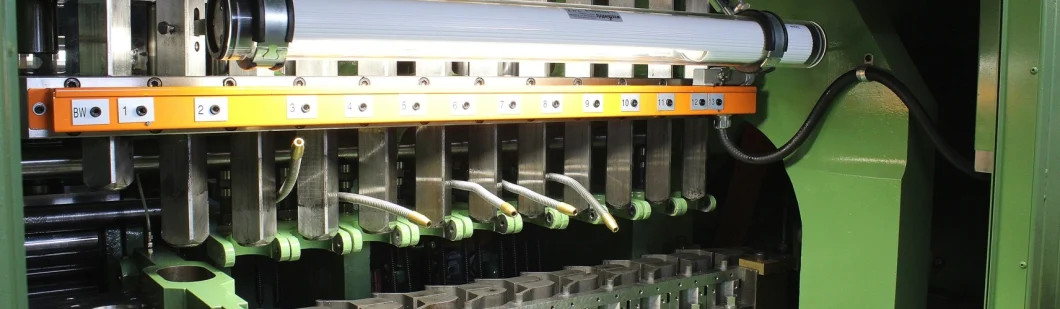

Number of stations 17

Number of rams 17

Capacity approx. on any one ram 9 tons with standard cams except slaves

Maximum shell height

Standard stroke cams 6″ (152mm)

Shell height 2.875″ (73mm)

High lift stroke cams 6.50″ (165mm)

Shell height 3.125″ (79mm)

Standard ram pitch 3.375" (85.7mm)

Maximum Blank Diameter

Single row blanking 3.25" (82.5mm)

Double row blanking 3.25" (82.5mm)

Motor 25HP 19Kw

Speed range per minute

Standard stroke cams 37-110*

Approximate floor space (excluding decoiler) 140" x 61" (3556x1550mm)

Approximate height 136" (3455mm)

Approximate weight 38,500lbs (17,500kg)

* Machine speed range stated is approximate; production rates are dependant on load, material and component configuration.

Pitch centres on certain machines can be reduced, increasing the number of stations available.

Shell height can be increased on certain machines by means of ram extenders.

On some machines certain blank diameters can be increased by fitting blank & cup units and / or wider transfer slides.

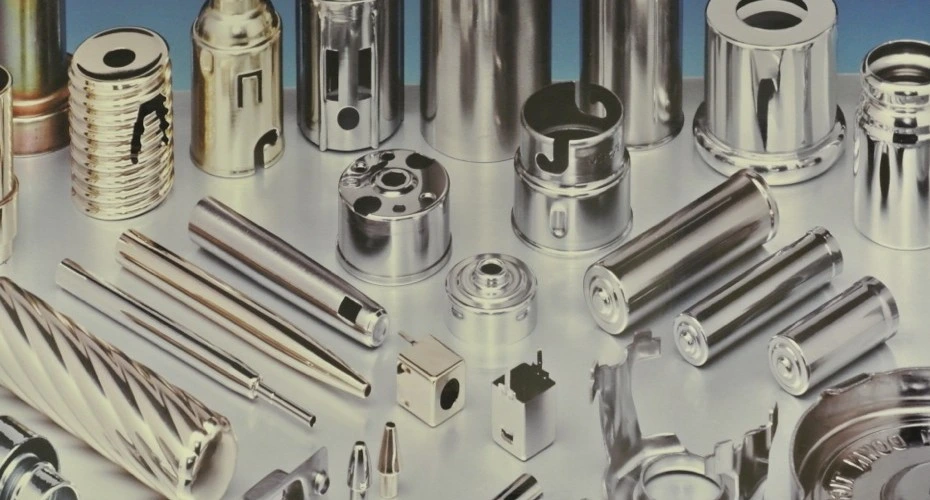

Automotive

Presses and tooling to manufacture miniature motor housings, valve stems, cigar lighters, hose ferrules, petrol filter bodies, quick connect connectors, airbag and ABS parts

Battery cans

We supply presses, tooling and further automation to all major battery manufacturers.

Pharmaceutical packaging

Presses and tooling to manufacture aluminium aerosol bottles, caps and stainless steel stems

Cosmetics

We supply presses and tooling custom built to make lipstick containers and perfume bottle caps

Pens and writing instruments

Deep drawn presses are perfectly suited to mass-produce pens and pen refills, lids and caps, barrels and ball point end tips

Needle bearing cases and heavy duty parts

We are only too happy to provide the perfect press, tooling and automation specification for any requirement. We supply all major manufacturers of pressed metal needle bearing cases and heavy duty parts such as plumbing and heating components.

Electrical

We custom build and supply presses and tooling to manufacture electrical light and lamp fittings, television parts, screening cans, as well as electronic components and their housing.

Household and specialist products

We supply presses and tooling to manufacture white goods as well as plumbing and heating components.