- Overview

- Company Advantage

- Company Profile

- FAQ

Basic Info.

Product Description

Bronze Press-Fit Elbow with Base Conformity of Connection The Press-fit elbow is a connection to make permanent and not reversible deform of the fittings on the pipe thus leading to a perfect mechanical joint, while the O-Ring provides for the hydraulic tightening connection. Pressing provides for a constant quality joining, easily reproduced and with a minimum physical effort by the operator. Major savings in installation time and cost compared with traditional jointing methods

The Press-fit elbow is a connection to make permanent and not reversible deform of the fittings on the pipe thus leading to a perfect mechanical joint, while the O-Ring provides for the hydraulic tightening connection. Pressing provides for a constant quality joining, easily reproduced and with a minimum physical effort by the operator. Major savings in installation time and cost compared with traditional jointing methods

Features

a. Material: C46500 or C69300

b.Connection: Made in four to seven seconds and ensures a consistent, strong, reliable, watertight seal

c.Suitable for hot and cold potable water, heating, gas, solar and fire protection systems..

Size

| ITEM CODE | T | ID |

| 0702896a | 1/2" | 12 |

| 0702897a | 1/2" | 15 |

| 0702898a | 1/2" | 18 |

| 0702899a | 3/4" | 22 |

Main Advantages of Press Fittings

a. Quick and safe installations

b. Excellent corrosion resistance

c. Reduced labor requirements

d. Easy handling and light weight

e.Dependability, even under severe use conditions

Application

1)Potable Water

2)Hydronic Heating

3)Chilled Water

4)Compressed Air

5)Vacuum

6)Oxygen, O2 (non medical)

Pressing Tool

with pressing jaws profile "V"

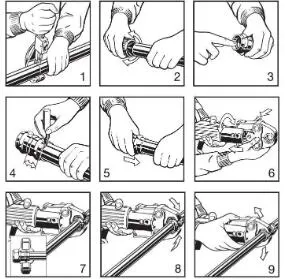

Installation Instruction

1) Cut copper tubing at right angles using displacement-type cuter or fine-toothed steel saw.

2) Remove burr from inside and outside of tubing to prevent cutting sealing element.

3) Check seal for correct fit. Do not use oils or lubricants.

4) Mark proper insertion depth on tubing.

5) While turning slightly, slide press fitting onto tubing to the marked depth.

6) Insert appropriate jaw into the pressing tool and push in,holding pin until it locks in place.

7) open the jaw and place at right angles on the fittings. Visually check insertion depth using mark on tubing.

8) Start pressing process and hold the trigger until the jaw has engaged the fitting.

9) After pressing, the jaw can be opened again.

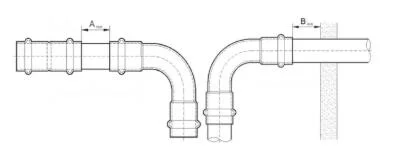

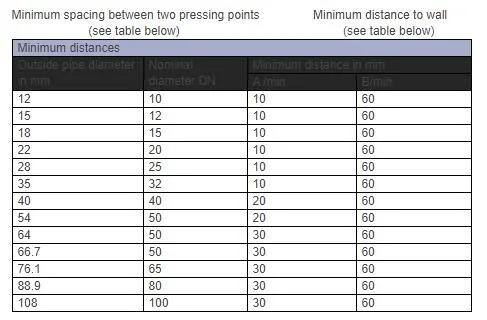

Space requirements

The pipe spacing in relation to walls, corners and slots, necessary for a secure installation is laid out in the drawings and tables below.

Delivery time and payment term

*Delivery time: Usually 35-45 days after receiving the order

*Payment term: 1) irrevocable L/C ; 2) T/T: 30%T/T paid in advance, 70% balance paid against the copy of B/L.

*High quality & industrial leading price

*Quick order processing & on-time delivery

*100% pressure leaking test during mass production to ensure high quality and long durability.

*100% QC inspection before shipment

*Innovative & customer-oriented

*Rich experience in exportation more than 30 years

*Modern technical equipment in combination with proficient manual work.

*Full production line including casting, forging, machining line, polishing line and assembling line.

*Rich experience in exporting business

*Innovation is the key to the development of our enterprise.

*Systematic management applied.

*Well equipped with modern test machines insuring reliability and endurance of products.

*Skilled engineers and workers.

*It can be produced by our own designs and brand or according to customers' samples, drawings.

*Samples for customer's confirmation is available

*OEM/ODM Service: Produce the products according to your drawings or samples.

Fada is a leading supplier of Faucet, serving a global marketplace. Fada operates two manufacturing plants in Zhejiang and Jiangxi, China. With more than 30 years manufacturing history, Fada rigidly carries the international Quality Management System standards and insists on everyday progress by striving for higher quality and a better service.

Q1: Are you a factory or trader?

A: We are a professional manufacturer for faucets,valves,fitting and floor drain for more than 25 years.

Q2: What is your MOQ?

A: For faucets,our MOQ usually is 1000PCS per item;for fitting,it depends on its size;for valve, our MOQ usually is 1500pcs.

Q3: Can your factory print our logo/brand on the product?

A: Our factory can laser print customer's logo on the product. Customers need to provide us a logo usage authorization letter to allow us to print customer's logo on the products.

Q4: Can I visit you?

A: Yes. Our factory is in Taizhou city,Zhejiang,China. Welcome to visit our factory, look forward to meeting with you.

Q5: How can I get some samples?

A: We usually provide pre-production samples before mass production after customer place order and make deposit.

Q6: What does EPDM stand for?

A: Ethylene-Propylene Diene Monomer

Q7: What are the most common errors made when installing s Press Fittings?

A: Not adequately deburring the end of the tubing, and not inserting the tube far enough into the press fitting.

Q8: What does with top mean?

A: There's a little nub inside which keeps you from inserting a pipe too far or not far enough. A no-stop fitting has no nub allowing you to put the fitting i when the pipes are fixed and can't be separated enough to put on a stop fitting.

Q8. What certificate do you have?

A: At present,we have UPC,NSF,DVGW,PED,LR, ISO9001, ISO14001 etc.