- Overview

- Product Description

- Product Details

- Features

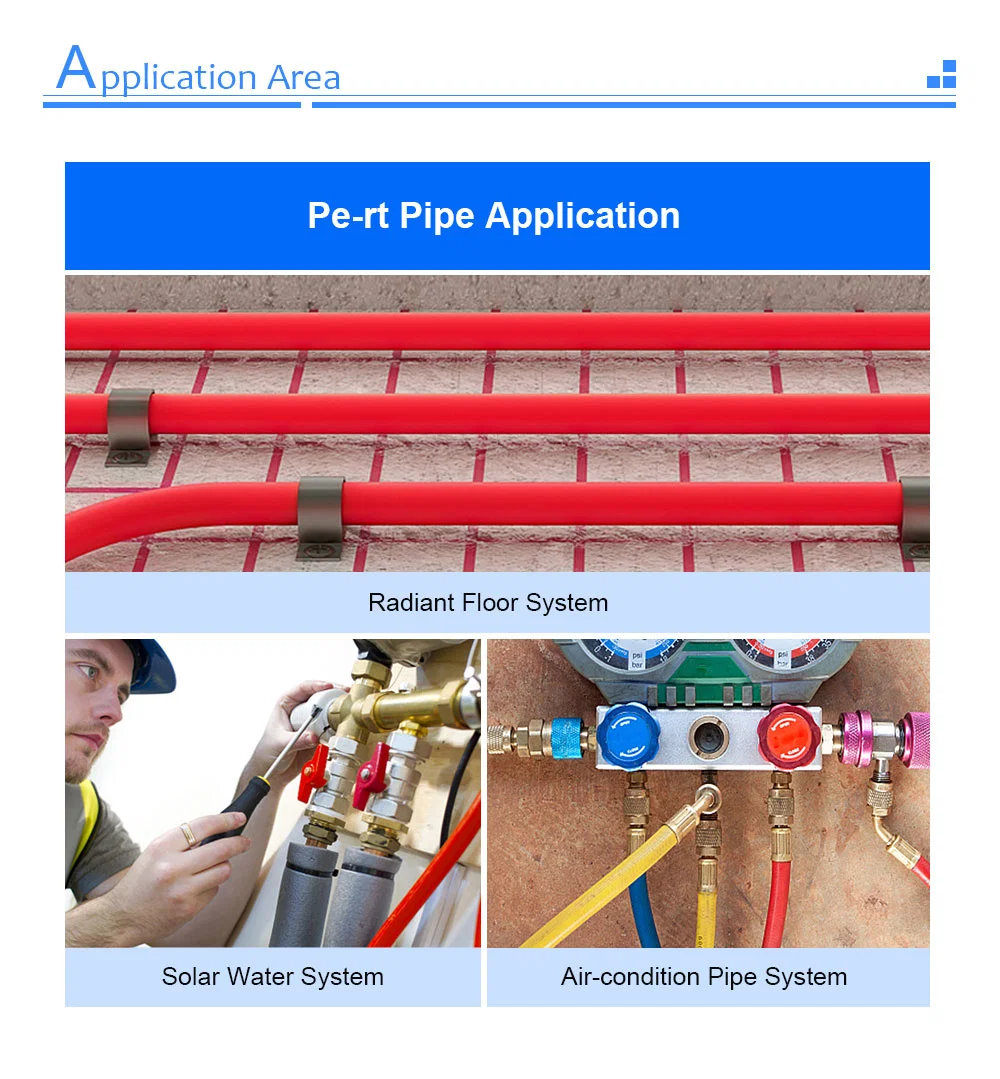

- Application Area

- Installation Steps

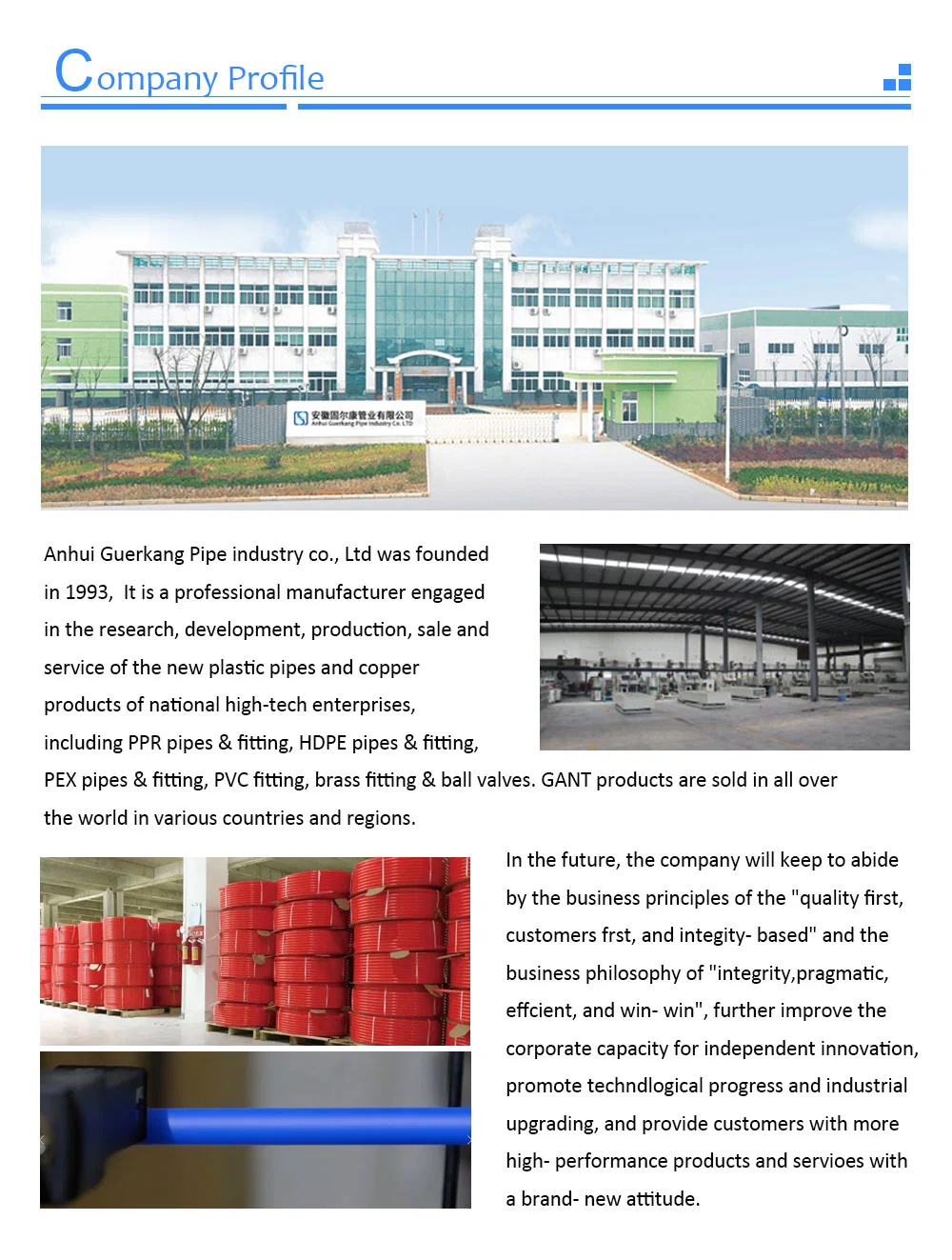

- Company Profile

- Certifications

- Packaging & Shipping

Basic Info.

Model NO.

PERT pipe-b

Tensile Strength

Curved Conveniently

Product Name

Radiant Heated Floor Pert Pex Pipe

Application

Under Floor Heating System

Color

Red/Bule/White/Orange/Grey/or Wha

Factory History

More Than 20 Years

Length

100/Rolls 200/Rolls, Custom

Thickness

as Customer Requirement, Custom

Standard

ISO 15875-2-2003, GB/T 18992.2-2003

Usage

Heating and Hot Water Systems

If Can Make Customer Logo

Can, 20000 Meter Can Logo

Quality

as Customer Requirement

OEM

Support

Free Samples

Support

Connection

Press

Advantage

Environment Friendly

MOQ

500 Meters

Transport Package

Packing in Rolls in Plastic Films, Customized

Specification

as customer requirement

Trademark

GANT, OEM

Origin

China, Anhui

HS Code

3917320000

Production Capacity

30000000meters

Product Description

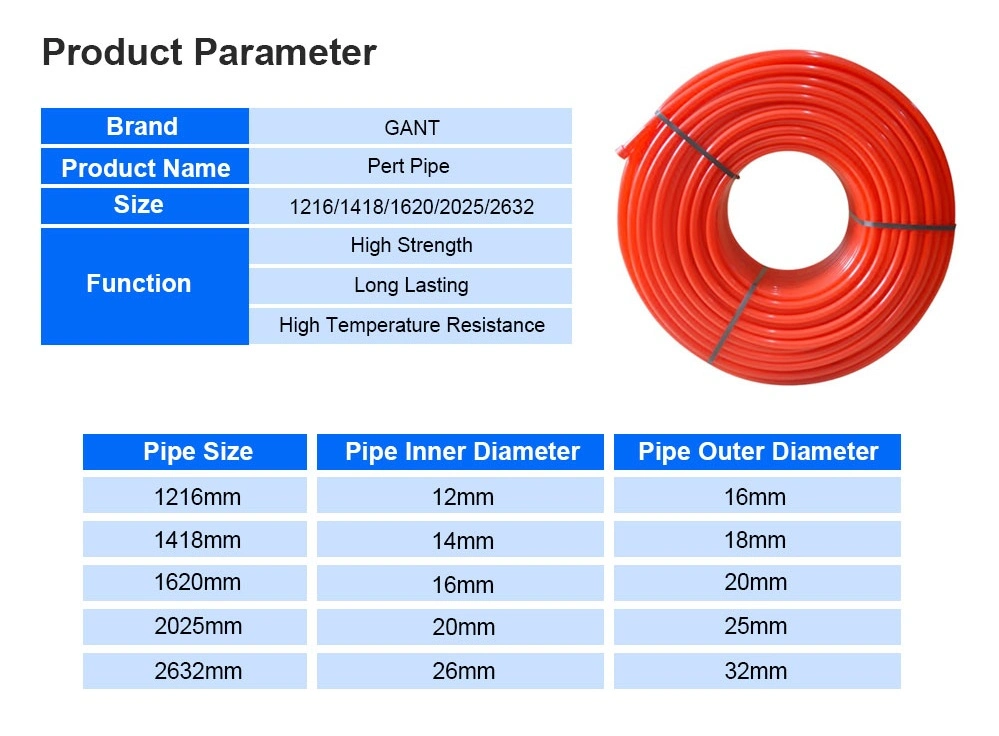

| Product Name | Pert Pipe |

| Color | Orange ,red,purple,customized |

| Working Temperature | -70ºC-110ºC |

| Size | 16-32mm |

| Meterial | Pe-rt |

| Working Preesure | Pn10 |

| Advantage | Oem&odm |

| Usage | Heating And Hot Water Systems |

| Performance | Good Flexibility, Easy To Bend |

| Certification | Iso 15875-2-2003, Gb/t 18992.2-2003 |

| Health Guarantee | The Interior Is Smooth, Not Easy To Corrode, And Does Not Form Scale |

| Serviceable Life | Over 20 Years |

| Oem | Accept |

| Feature | Corrosion Resistant |

| Healthy | Environmentally Friendly |

| Package | Roll Package |

Definition

Pe-Rt Is A Polyethylene (Pe) Resin In Which The Molecular Architecture Has Been Designed Such That A Sufficient Number Of Tie Chains Are Incorporated To Allow Operation At Elevated Or Raised Temperatures (Rt). Tie Chains "Tie" Together The Crystalline Structures In The Polymer, Resulting In Improved Properties Such As Elevated Temperature Strength And Performance, Chemical Resistance And Resistance To Slow Crack Growth.

Overview

Pe-Rt Is A High-Temperature Flexible Plastic Pressure Pipe With A 35-Year History Of Successful Use In The European Market With Extensive Testing For Durability And Material Performance. It Was First Introduced In North America In 2003 And Is Used In Aluminum Composite (Multilayer) Barrier Tubing And Solid Wall Tubing And Pipe. Applications Include Plumbing, Water Service, Hydronic Heating And Cooling, Snow And Ice Melting And Ground Source Geothermal Piping Systems. Pe-Rt Is Approved In All Model Plumbing And Mechanical Codes Across The United States.

Pe-Rt Applications

Hot And Cold Water Plumbing Distribution, Residential And Commercial

Radiant Heating And Cooling Systems (Floors, Walls, Ceilings)

Hydronic Piping And Distribution (Radiators, Fan Coils, Etc.)

Chilled Water Piping

Outdoor Snow And Ice Melting

Turf Conditioning/Pitch Heating

District Heating/Cooling

Water Service Lines

Geothermal Ground Loops (Vertical Boreholes, Horizontal Layouts)

Pe-Rt Advantages

Safety Of Potable Water And Long-Term Reliability

Resistance To Corrosion, Tuberculation, Deposits

Flexibility To Speed Installations

Freeze-Break Resistance

Lightweight, Easy To Transport

Noise And Water Hammer Resistance

Low Scrap Value, Avoiding Jobsite Theft

Durability And Toughness To Survive Jobsite Installations

No Flame Used For Joining, With Many Fitting And Joining Options

Recyclable, Eco-Friendly Material

Heat Fusible For Virtually Leak-Free Performance

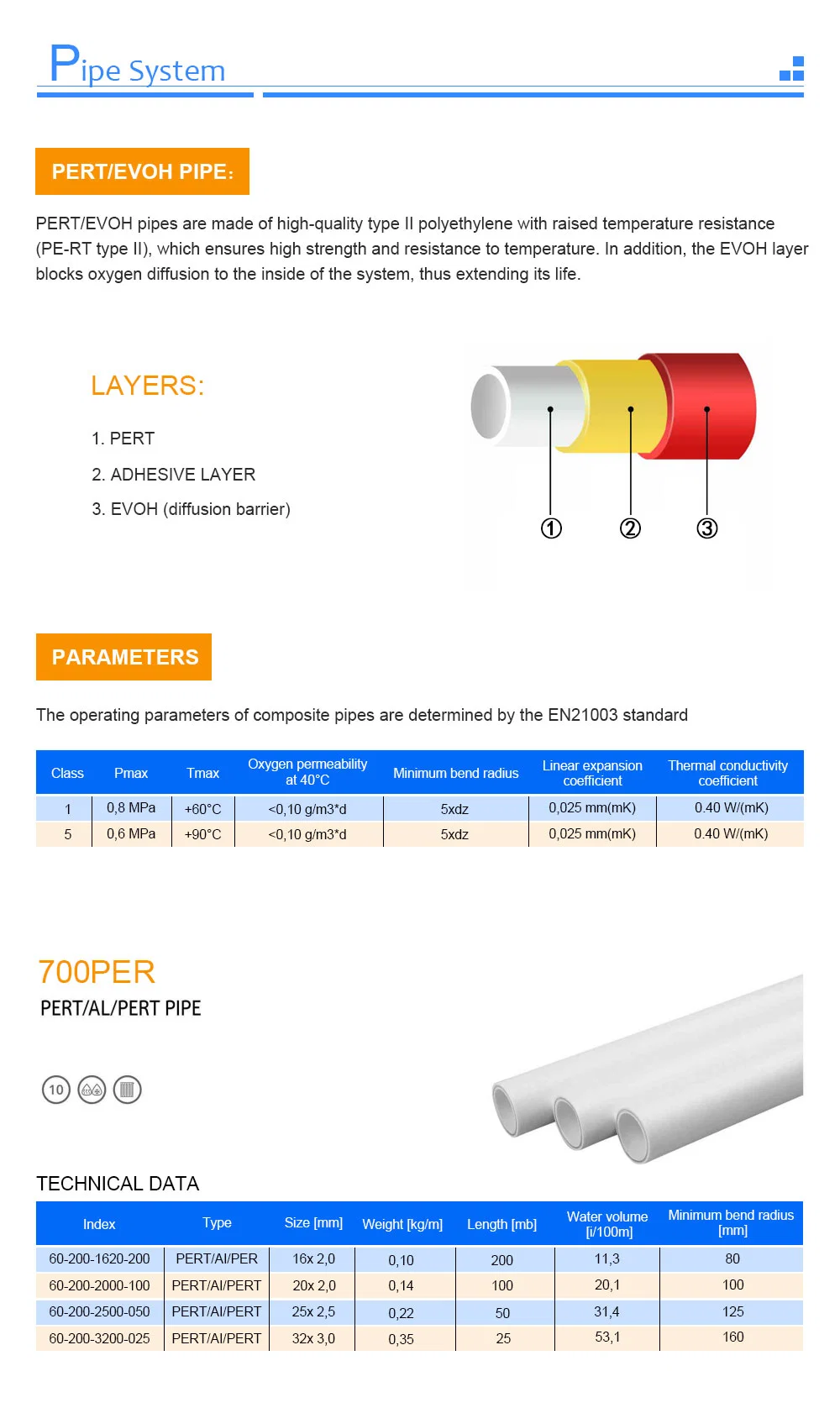

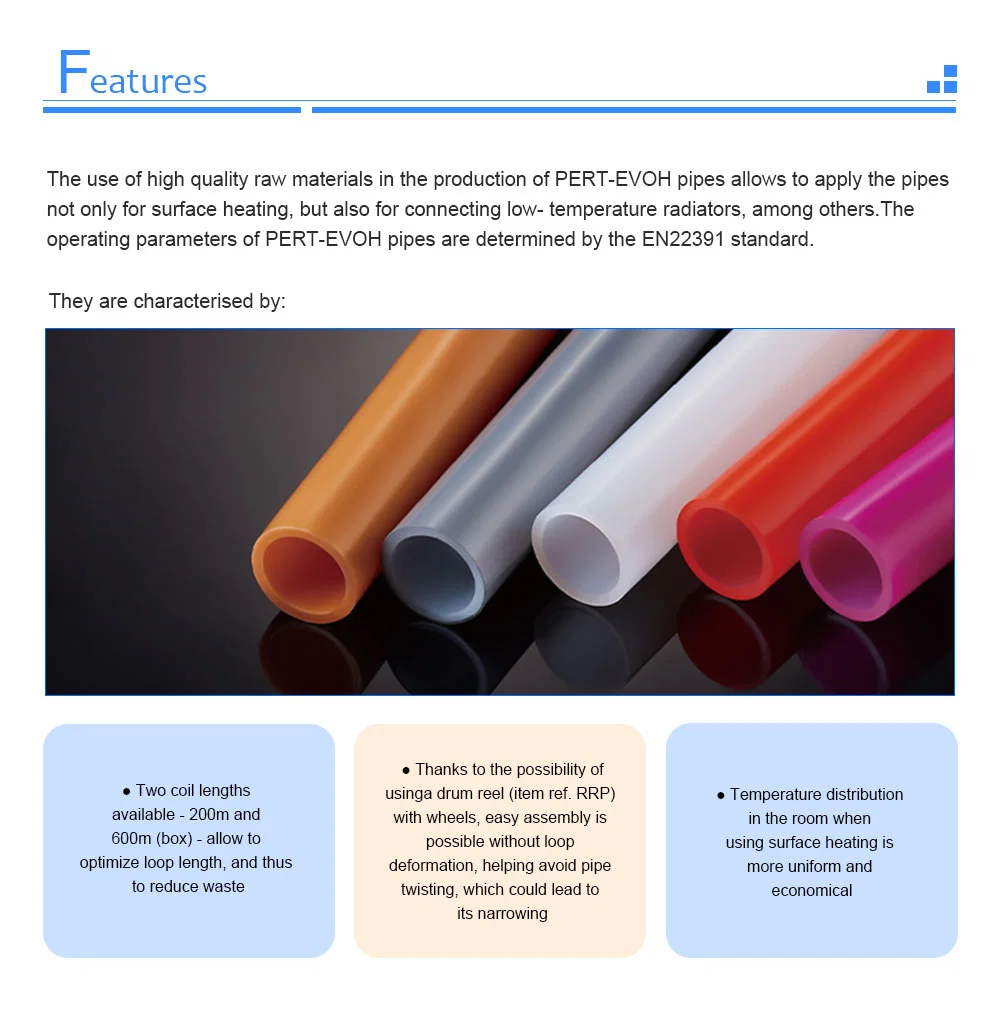

Light Weight And Ultra-flexible, Evoh Pert Barrier Pipe Is The Ideal Solution For Large Installations Where The Absence Of A Metal Layer Makes It Less Taxing To Bend And Install Than Pert-al-pert Pipe Without Sacrificing Performance.

Our 16mm Evoh Pert Pipe Is Manufactured To Iso9001 Standards Ensuring Outstanding Performance & Reliability In All Types Of Warm Water Underfloor Heating Systems.

Evoh Pe-rt Pipe Consists Of 3 Layers Which Is Made Up Of An Oxygen Barrier (evoh), A Layer Of Adhesive, And An Inner Layer Of Pert Pipe.

The Oxygen Diffusion Barrier Encases The Inner Layer Of Pe-rt Pipe Completely To Prevent The Entry Of Oxygen Into The Heating System Through The Pipe. The Tough Outer Layer Is Designed To Withstand The Demands Of A Worksite Ensuring The Oxygen Barrier Remains Intact, Which Reduces The Risk Of Corrosion Within The Heating System.

Key Features:

Very Easy To Bend

High Heat Transfer

Lightweight And Easier To Handle Than Multilayer Pert-al-pert Pipe

Perfectly Suited For Overlay Boards

Cannot Be Used Above 70°c Making It Perfectly Suited For Underfloor Heating

Not For Domestic Plumbing, Made Best For Underfloor Heating Systems